Smart Sensors vs. Traditional: Is the Cost Worth It?

The most expensive thing in your factory is not the robot. It is not the raw material. It is the unplanned downtime. On paper, a traditional sensor looks like the best choice. It is cheap. It is simple. It costs 20 dollars. A smart sensor looks expensive. It costs 100 dollars. If you look only at the purchase price, the choice is easy. You buy the cheap one.

But this logic is flawed. It ignores the reality of modern manufacturing. When a cheap sensor fails, it does not tell you. It simply stops. The machine crashes. The production line halts. You lose thousands of dollars in minutes. The 80 dollars you saved on the sensor is gone.

We will analyze the Total Cost of Ownership (TCO). We will compare the data architecture. And we will help you answer the critical question: When does the expensive sensor actually make you money?

Defining the Contenders

To make a fair comparison, we must understand the technology under the hood. The difference is not just marketing. It is physics and logic.

The Traditional Sensor: The "Passive Reporter"

A traditional sensor is an analog device. Think of a standard thermocouple or an inductive switch.

Function: It detects a physical change.

Output: It sends a continuous voltage or current.

Limitation: It is blind to its own condition. It has no memory. It has no serial number. It blindly sends a signal. If the wire is cut, the signal drops to zero. But the controller does not know if the temperature is truly zero or if the wire is broken. It requires human interpretation.

The Smart Sensor: The "Active Analyst"

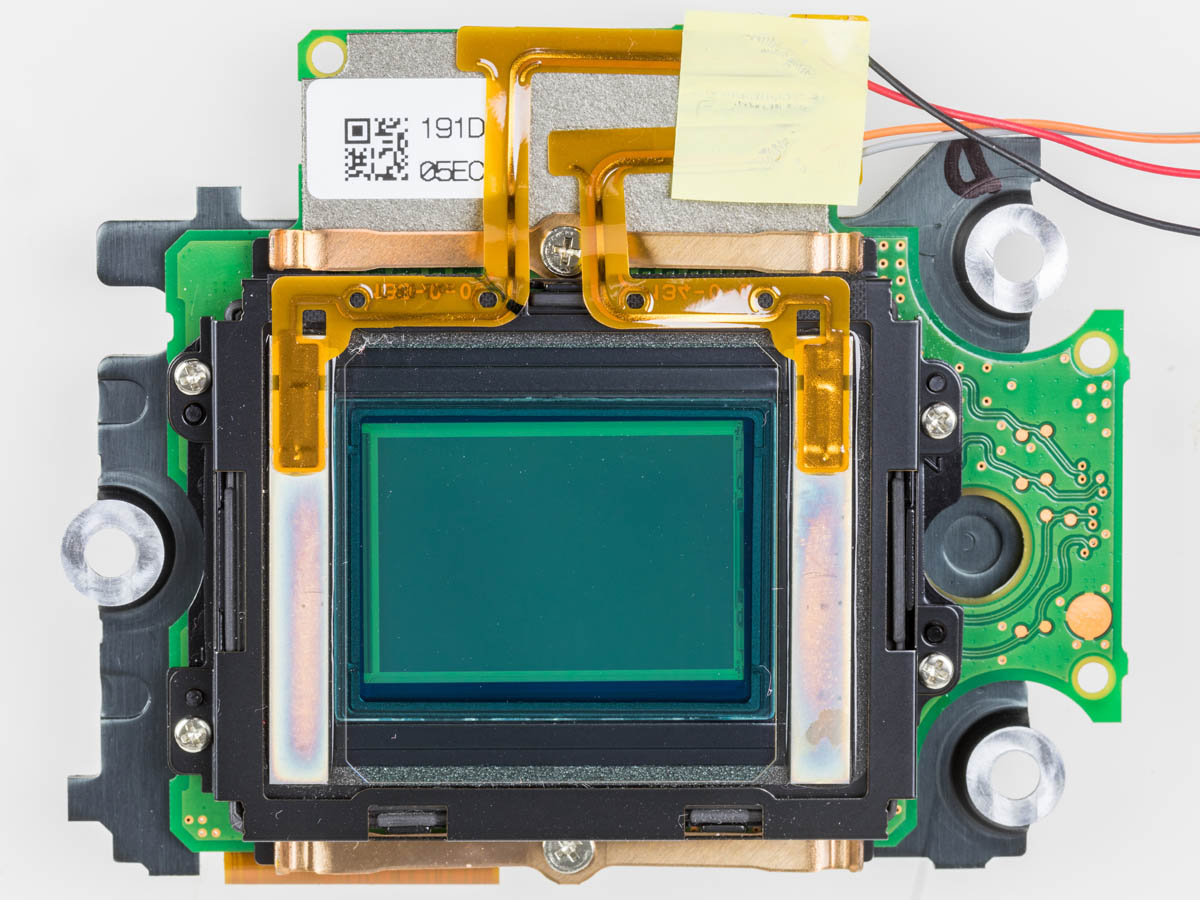

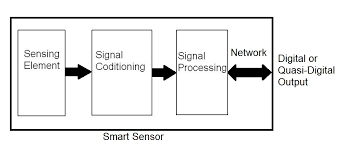

A smart sensor is a digital device. It contains a microcontroller. It is an edge computing device.

Function: It detects a physical change and processes it.

Output: It sends a digital data packet (via protocols like IO-Link).

Advantage: It transmits metadata. It sends the temperature value, but it also sends the sensor status, the signal quality, and the operating hours. It validates its own data before sending it.

The Connectivity Architecture

The way these sensors connect to your system defines your entire machine architecture.

Analog Systems (The Legacy Standard)

Traditional sensors mostly use the 4-20mA loop. This standard is reliable. It has existed for decades. It is immune to some electrical noise. But it is a "dumb" connection.

Information flows one way only. From sensor to controller. You cannot send data back to the sensor. If you need to change the sensing range, you cannot do it from the control room. You must send a technician to the machine. They must open the housing. They must turn a screw. This is slow. And it introduces human error.

Digital Systems (The IO-Link Revolution)

Smart sensors use bi-directional communication. IO-Link is the dominant standard in 2025. It uses the same standard cables as analog sensors. But the data is digital.

This allows for "Parameterization."

Imagine you are running a packaging line. You switch from a black box to a white box.

With Analog: You must manually adjust the sensitivity of every optical sensor.

With Smart: The PLC sends a command: "Load Profile B." Every sensor updates its sensitivity instantly. The changeover time drops from one hour to one second.

The True Cost Analysis

Let us break down the money. We will use a hypothetical production line with 50 sensors to demonstrate the math.

The Upfront Hardware Cost

This is where traditional sensors win.

Traditional Approach: You buy 50 standard sensors at 25 dollars each. Total cost: 1,250 dollars.

Smart Approach: You buy 50 smart sensors at 75 dollars each. You also need an IO-Link Master block, which costs 300 dollars. Total cost: 4,050 dollars.

The gap is nearly 3,000 dollars. If your budget is tight, this is hard to swallow. But you must look at Year 1 operations.

The Commissioning Cost (Time)

Hardware is cheap. Labor is expensive.

Connecting and calibrating analog sensors is manual work. You must scale the analog signal in the PLC. You must test the voltage.

Estimated Labor: 30 minutes per sensor. Total: 25 hours. At 100 dollars per hour, that is 2,500 dollars.

Smart sensors are "Plug and Play." You plug them in. The Master block detects them. It downloads the parameters automatically.

Estimated Labor: 5 minutes per sensor. Total: 4 hours. Cost: 400 dollars.

Current Score: The price gap has now closed significantly. The smart system is faster to build.

The "One Incident" Calculation

Now, consider a failure. A standard sensor fails on a Tuesday afternoon.

The machine stops. The maintenance team does not know which sensor failed. They spend 45 minutes troubleshooting with a multimeter.

If your downtime cost is 500 dollars per minute, that 45-minute stop cost you 22,500 dollars.

With a smart sensor, the system sends an alert: "Sensor 12 is disconnected." The team goes straight to Sensor 12. They replace it. The Master block automatically uploads the settings to the new sensor. The machine runs again in 10 minutes. The cost is 5,000 dollars.

The Verdict: In just one failure event, the smart system saved 17,500 dollars. The initial extra cost of the hardware is irrelevant compared to this saving.

Predictive Maintenance vs. Reactive Repair

The industry is moving from "Repair it when it breaks" to "Fix it before it breaks." Only smart sensors enable this.

Internal Diagnostics

A traditional sensor works until it dies. A smart sensor knows it is dying.

For example, optical sensors (photoelectric eyes) are very common. They fail because dust covers the lens.

Traditional: The dust builds up. The signal gets weak. Eventually, the sensor stops seeing the target. The machine stops.

Smart: The sensor monitors the "Gain Reserve." It knows how much light is coming back. When the light drops to 60%, it sends a "Maintenance Required" signal. It is still working, but it needs cleaning. You clean it during the next break. No downtime occurs.

Environmental Monitoring

Smart sensors often measure secondary data. A proximity sensor measures distance, but it also measures internal temperature.

If a bearing on your conveyor belt starts to fail, it generates heat. The sensor mounted nearby heats up. The smart sensor reports this rise in temperature.

Suddenly, your proximity sensor is also acting as a thermal monitor. It gives you clues about the machine's health without buying extra hardware.

Data Integrity and Accuracy

In the age of AI, data quality is king. You cannot train an AI model on bad data.

The Noise Problem

Factories are noisy places electrically. Large motors, variable frequency drives (VFDs), and welding equipment create electromagnetic interference (EMI). In an analog cable, this noise induces voltage spikes. A 5-volt signal might briefly become 5.5 volts. The controller reads this as a spike in pressure or temperature. It is a false reading.

The Digital Solution

Smart sensors transmit binary code (0s and 1s). It is very hard for electrical noise to turn a 0 into a 1. This means the data you see on your dashboard is exactly what the sensor measured. There is no degradation over long cables.

Also, smart sensors are factory calibrated. You do not need to calibrate the analog input card on the PLC. This eliminates another source of error.

Real World Implementation Scenarios

To help you decide, here are three scenarios where the choice is clear.

Scenario A: The Standalone Pump

You have a simple water pump. It fills a tank. If it breaks, you have a second pump.

Verdict: Use Traditional Sensors.

Why? The cost of failure is low. The system is simple. You do not need complex data. A standard float switch is enough.

Scenario B: The Automotive Assembly Line

You are welding car bodies. The precision must be perfect. If the line stops, 500 workers stand idle.

Verdict: Use Smart Sensors.

Why? The cost of downtime is massive. You need the diagnostic data. You need to know if a sensor cable is fraying before it snaps. The investment is an insurance policy.

Scenario C: The Food and Beverage Plant

You produce milk. You must wash the machine with hot chemicals every night (CIP Process).

Verdict: Use Smart Sensors.

Why? You need sensors that can report their serial numbers. You need to prove to the auditors that the sensor used for pasteurization was calibrated. A smart sensor stores its last calibration date in its memory. You can download this for your compliance report automatically.

Overcoming the Barriers

If smart sensors are so good, why isn't everyone using them? There are hurdles you must prepare for.

The Skill Gap

This is the biggest problem. An electrician with 30 years of experience knows how to troubleshoot a 4-20mA loop with a multimeter. He can see the current.

With smart sensors, you cannot see the signal with a meter. You need a laptop. You need software. You need to understand IP addresses and logic.

Solution: You must train your maintenance team. Do not just install the hardware and leave. Give them the tools to read the data.

The Security Risk

Connecting sensors to a network creates a new entry point for cyber attacks. If a hacker reaches the IO-Link Master, they could change the sensor parameters. They could shut down the machine.

Solution: Practice "Defense in Depth." Keep your sensor network separate from your office network. Use firewalls. Never connect sensor masters directly to the public internet.

The Future of Sensing

The technology does not stand still. We are already seeing the next generation.

Wireless and Battery-Free

Cables are the weakest part of any sensor system. They break. They get expensive to route. New smart sensors use "Energy Harvesting." They take energy from the vibration of the machine or the heat of the pipe. They do not need batteries. They send data via Bluetooth or LoRaWAN. This makes installation almost free. You just stick the sensor on the machine.

Sensor Fusion

In the past, you bought one sensor for heat, one for vibration, and one for pressure.

New "Multi-sensing" units combine these. One small box measures everything. It uses onboard AI to look for patterns. It tells you "The motor is healthy" or "The motor is failing." It does the analysis for you.

The Strategic Choice

The debate between smart and traditional sensors is not really about sensors. It is about your business strategy. If your strategy is to minimize the initial build cost, traditional sensors are the right choice. They work. They are proven.

But if your strategy is to maximize efficiency, reduce downtime, and gather data for AI, then smart sensors are the only choice. The extra cost is not an expense. It is an investment. It pays for itself in the first year of operation.

Do not look at the price tag of the sensor. Look at the price of the problem it solves. In 2025, data is the most valuable asset you have. Smart sensors are the only way to capture it.

Ready to Upgrade? Choose Joydo.

Whether you decide to stick with reliable traditional sensors or upgrade to smart IO-Link systems, one thing is true: You cannot afford to wait.

When a machine stops, you need parts immediately. You do not want to hear "6 weeks lead time."

This is where Joydo helps you.

We are your trusted partner for industrial automation. We understand that time is money.

Massive Stock: We hold a large inventory of both smart and traditional sensors. We are ready to ship when you need it.

100% Original: We only sell authentic, original factory parts. No fakes. No clones. You get the exact performance you pay for.

Fast Service: We help you find the right part fast, so you can get your machine running again.

Do not let a missing sensor stop your factory. Check our stock at Joydo today and keep your production moving.