ISO-Certified Industrial Sensor Supply Chain Solution

Supply chain resilience has become the most critical factor for manufacturing success in 2025. For procurement managers and automation engineers in North America and Europe, the challenge is clear: maintaining production uptime despite fluctuating global inventory levels. When a critical production line stops due to a missing sensor, the cost is measured in thousands of dollars per minute.

Traditional distribution channels often struggle to meet immediate demands, frequently quoting lead times exceeding 40 weeks. Joydo Electronics (www.joydo-ele.com) operates differently. As an independent stocking distributor, offering immediate availability of high-demand industrial sensors is our core mission.

However, availability is nothing without reliability. This comprehensive guide outlines how Joydo Electronics combines massive inventory levels with ISO 9001 certified quality control to serve as a trusted partner for the global automation industry.

The Strategic Value of Independent Stocking Distributors

Why do leading automotive and medical manufacturers turn to independent distributors? The answer lies in flexibility and speed.

Authorized franchise distributors are often restricted by the manufacturing output of the original factory. If the factory delays production, the distributor has no stock. Conversely, independent distributors like Joydo operate with a decentralized sourcing model.

Bridging the Supply Gap

Market volatility requires a buffer. Joydo Electronics acts as this strategic buffer by:

1、Pre-purchasing Inventory: Stock is acquired based on market analysis before shortages occur.

2、Global Sourcing Network: Access to inventory pools in Asia that are often inaccessible to Western buyers.

3、Shortening Lead Times: Reducing delivery windows from months to days.

By maintaining physical stock of critical components, specifically automation sensors, production continuity is ensured for our clients.

Technical Inventory Breakdown – Industrial Sensors

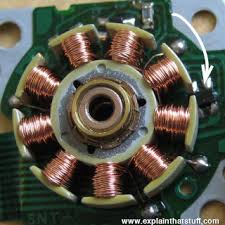

Sensors serve as the sensory nervous system of Industry 4.0. Our warehouse maintains a diverse portfolio of sensor technologies, ranging from basic detection to advanced measurement.

Below is a detailed technical analysis of the sensor categories currently available for immediate dispatch.

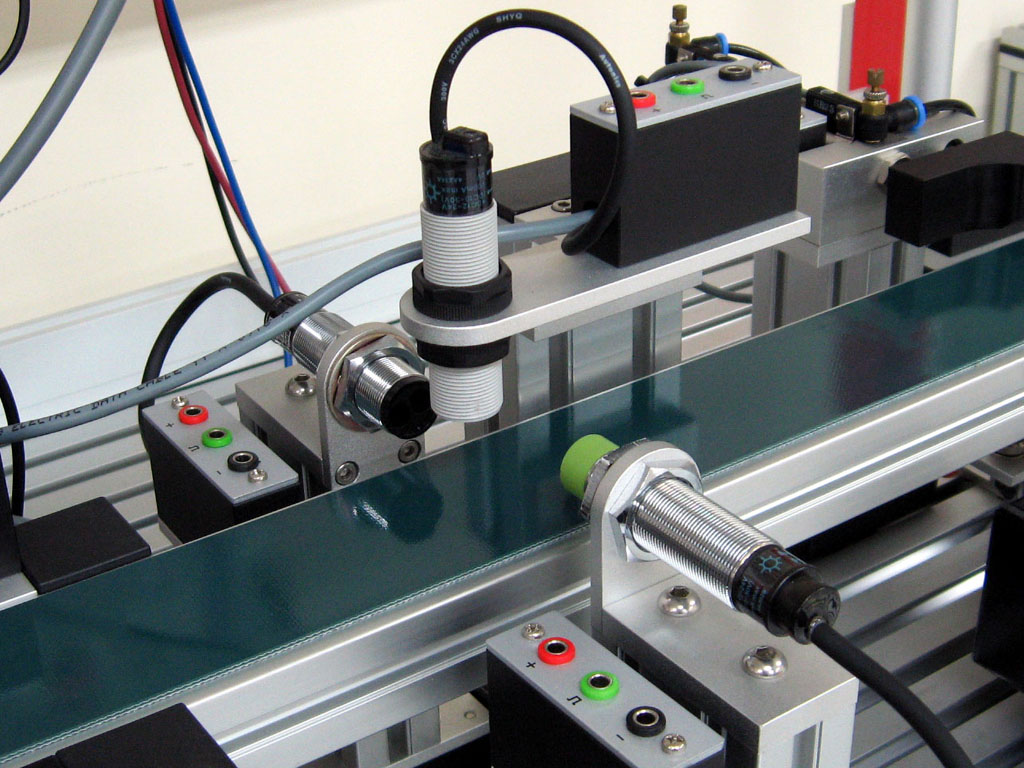

Inductive and Capacitive Proximity Sensors

Proximity detection is fundamental to automation. These components must withstand harsh industrial environments, including vibration, oil, and dust.

1、Inductive Sensors: Utilizing electromagnetic fields to detect metallic objects, these are essential for positioning and speed detection. Our stock includes cylindrical models (M8, M12, M18, M30) and rectangular block styles from brands like Omron and Keyence. Shielded versions are available for flush mounting, while unshielded versions offer longer sensing distances.

2、Capacitive Sensors: These utilize electrostatic fields to detect non-metallic targets, including liquids, granules, and plastics. They are critical for level control in the food processing and packaging industries.

Inventory Highlight: High-temperature and wash-down rated (IP69K) models are often in stock, catering to food and beverage hygiene standards.

Photoelectric Sensors (Optical Detection)

For longer sensing ranges and varied target materials, optical sensors are the standard.

1、Through-Beam: Offering the longest range and highest excess gain, making them ideal for dirty environments.

2、Retro-Reflective: Utilizing a reflector for installation simplicity. Polarized models are available to reliably detect shiny objects.

3、Diffuse-Reflective: The sensor relies on light reflected directly from the target. Background suppression models are stocked to ignore objects beyond a set distance.

Expert Insight: Many legacy optical sensors from Sick and Banner are no longer produced. Joydo specializes in sourcing these EOL (End of Life) optical units to prevent the need for system redesigns.

Pressure Transducers and Sensors

Precise fluid and gas monitoring is non-negotiable for safety.

1、Piezoelectric Sensors: Ideal for measuring dynamic pressure changes in high-speed applications.

2、Strain Gauge Sensors: Providing excellent stability and accuracy for static pressure measurement in hydraulic systems.

3、Differential Pressure: Essential for HVAC systems to monitor filter performance and airflow.

Stock includes heavy-duty stainless steel transducers capable of withstanding pressures up to 5000 PSI, suitable for oil and gas applications.

Environmental Sensors (Temperature & Humidity)

Thermal management protects sensitive electronics and ensures process integrity.

1、RTDs (Resistance Temperature Detectors): Platinum sensors (Pt100, Pt1000) offer superior stability and accuracy over a wide temperature range compared to thermocouples.

2、Thermistors (NTC/PTC): Cost-effective solutions for over-temperature protection in power supplies and battery packs.

3、MEMS Environmental Units: Integrated chips combining temperature, humidity, and pressure sensing for IoT devices.

Inertial Measurement Units (MEMS)

The demand for accelerometers and gyroscopes has surged due to the drone and robotics sectors. Micro-Electro-Mechanical Systems (MEMS) combine mechanical and electrical components on a microscopic scale.

Sourcing these components has become difficult due to high demand in consumer electronics. Joydo maintains a strategic reserve of industrial-grade MEMS sensors from Bosch and STMicroelectronics ensuring stability for robotics development.

Quality Assurance Framework

In the electronic distribution market, trust is binary: it either exists, or business ceases. The primary concern for any buyer procurement manager is counterfeit components.

To mitigate this risk, Joydo Electronics operates under a rigorous Quality Management System (QMS).

ISO 9001:2015 Certification

Operations are not conducted randomly. Certification to ISO 9001:2015 standards indicates that every process—from supplier vetting to final dispatch—is documented, repeatable, and auditable.

Vendor Management: Suppliers are graded based on historical performance.

Corrective Actions: Any deviation triggers a formal root-cause analysis (CAPA).

The Anti-Counterfeit Laboratory

Verification of authenticity is not limited to visual checks. A multi-layered testing protocol, aligned with industry standards such as IDEA-STD-1010, is employed.

Visual Microscopy Inspection

Components are examined under high-magnification (40x - 100x). Inspectors look for:

1、Inconsistent laser marking or fonts.

2、Evidence of "blacktopping" (resurfacing used chips).

3、Oxidation on leads or pins indicative of prior use.

Solvency Testing (Acetone/1-Methyl 2-Pyrrolidinone)

Counterfeiters often reprint markings using low-quality ink. Swabbing the surface with specific solvents reveals if the top coating or marking is chemically unstable, a clear sign of counterfeiting. Original manufacturer markings are cured and solvent-resistant.

X-Ray Fluorescence (XRF) & X-Ray Imaging

For complex sensors and ICs, non-destructive X-Ray analysis is utilized.

1、Internal Structure: Verifying the die size and wire bonding patterns match the original manufacturer’s datasheet.

2、Lead Frame Analysis: Checking for consistency in the metal lead frame.

Solderability Testing

In accordance with ANSI/J-STD-002, terminals are tested to ensure they will solder correctly during your manufacturing process. Aged components with oxidized leads are rejected to prevent production failures.

Managing Obsolescence and EOL Components

Product lifecycles in the semiconductor industry are shorter than the lifecycles of industrial machinery. A machine built in 2010 may work perfectly, but the sensors required for maintenance may have been discontinued (EOL) in 2020.

Redesigning a circuit board or retrofitting a machine to accept a new sensor is expensive and time-consuming.

The Joydo Solution:

Specialization in obsolete component sourcing allows us to support legacy systems.

1、Strategic Buyouts: Inventory is often acquired from excess stock of large OEM (Original Equipment Manufacturer) factories.

2、Global Warehouse Access: Connections with warehouse networks in Japan and Europe allow the location of "New Old Stock" (NOS)—parts that are out of production but remain brand new in original packaging.

This capability extends the operational life of your capital equipment, providing a significant return on investment (ROI).

Logistics and Global Fulfillment

Possessing the stock is only the first step; delivering it intact is the second. Sensors are sensitive devices, susceptible to damage from Electrostatic Discharge (ESD) and moisture.

Packaging Standards

All shipments adhere to ANSI/ESD S20.20 standards.

1、Active Components: Sealed in metallized static shielding bags.

2、Moisture Sensitivity: Humidity Indicator Cards (HIC) and Desiccant packs are included for Moisture Sensitive Devices (MSD), following JEDEC J-STD-033 guidelines.

3、Physical Protection: Heavy-duty cartons and high-density foam prevent mechanical damage during transit.

Shipping Velocity

Downtime is expensive. Therefore, standard shipping methods are bypassed in favor of express services.

Through partnerships with DHL, FedEx, and UPS, transit times are minimized:

1、North America: 2-4 business days.

2、Western Europe: 3-5 business days.

3、Asia Pacific: 1-2 business days.

Customs documentation is meticulously prepared to ensure correct Harmonized System (HS) codes are used, preventing delays at the border.

Case Studies – Serving Diverse Industries

The application of sensors spans across every sector of the modern economy. Joydo Electronics supports a wide array of vertical markets.

Automotive Manufacturing

Tier 1 and Tier 2 suppliers require strict adherence to quality. From Hall Effect sensors for crankshaft positioning to pressure sensors for braking systems, our components support the automotive supply chain. Availability of AEC-Q100 qualified parts is prioritized.

Medical Technology

Reliability in healthcare is non-negotiable. We supply precision pressure sensors for ventilators and temperature sensors for laboratory refrigeration units. During global supply crunches, our stock has been instrumental in keeping medical device production lines active.

Renewable Energy

Solar inverters and wind turbines rely on current sensors and environmental monitors. These components must endure extreme weather conditions. High-reliability, ruggedized sensors are stocked to support the green energy transition.

Purchasing Guide (Seamless Procurement)

Navigating the procurement process at Joydo Electronics is designed for efficiency.

Digital Inventory Search

The website features a real-time search engine. Entering a part number reveals availability immediately. If a specific "Obsolete" part is not listed, it does not mean it is unavailable.

Request for Quote (RFQ)

For high-volume orders or hard-to-find items, the RFQ system connects buyers directly with senior account managers.

BOM Management: Entire Bill of Materials lists can be uploaded. The team will scrub the list, identifying crosses for obsolete parts and offering volume pricing for active parts.

Order Confirmation and Traceability

Upon order placement, a Sales Order confirmation including date codes and manufacturer details is issued. This ensures transparency before the product ever leaves the warehouse.

Conclusion: Securing Your Supply Chain

Uncertainty is the enemy of production. In an era of component shortages and extended lead times, relying solely on traditional distribution channels introduces unnecessary risk.

Joydo Electronics offers a verified, secure, and immediate alternative.

By combining ISO 9001 certified quality processes with a massive inventory of industrial sensors, the gap between requirement and delivery is bridged. Whether sourcing a replacement for an obsolete optical sensor or procuring 10,000 units of a pressure transducer for a new product, the solution is in stock.

Do not let supply chain disruption dictate your production schedule. Regain control by partnering with a distributor that prioritizes availability and integrity.