How Are Industrial Sensors Manufactured?

We use technology every day. But we rarely think about how it is made. In the world of industrial automation, one device is very common. This device is the proximity sensor. It is the eyes of the machine. It tells the robot when to stop. It tells the conveyor belt when to move. But how do we take raw metal and plastic and turn them into a smart proximity sensor?

This is a long and precise process. It involves electrical engineering, mechanical assembly, and chemical sealing. It requires very expensive machines and skilled workers. This guide will take you through every single step. We will start with the raw materials. We will end with the final box.

Design and Raw Materials

Before a factory can make a single unit, they must plan everything. This is the design phase. A proximity sensor looks simple on the outside. It looks like a metal tube. But inside, it is complex.

The Engineering Design

Engineers use computer programs to draw the sensor. They need to decide many things. For example, they need to decide the sensor's detection range, also known as its sensing range. They also need to determine whether the sensor can detect iron, aluminum, or copper.

They also design the circuit board. This is the brain of the sensor. The board must be very small. It has to fit inside a tube that is sometimes only 4 millimeters wide. This makes the design very hard. The engineers must place the parts perfectly. If they make a mistake, the sensor will get too hot. Or it will not work when there is noise from other machines.

Selecting the Raw Materials

A good product starts with good materials. The factory buys materials from all over the world.

The Housing Material: Most sensors use metal for the body. The most common metal is brass. But brass can rust. So, the factory coats the brass with nickel. This is called nickel-plated brass. It is shiny and strong. For food factories, they use stainless steel.

This steel is cleaner and safer.

The Sensing Face: The front of the sensor cannot be metal. Metal would block the signal. So, they use plastic. They use a special plastic called PBT or LCP. These plastics are very hard. They do not break if you hit them. They also handle heat very well.

The Coil Wire: This is very important for an inductive proximity sensor. The wire is made of copper. It must be very pure. It is coated with a thin layer of insulation. This wire is thinner than your hair.

The PCB: The circuit board is made of fiberglass and epoxy. This material is called FR4. It is strong and does not burn easily.

The Potting Compound: This is the glue that fills the sensor. It is usually an epoxy resin or silicone. It starts as a liquid and turns into a solid.

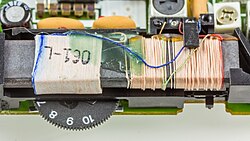

The Coil Assembly

Now the manufacturing begins. The first part we make is the coil. The coil is the most important part of an inductive proximity sensor. It is the part that creates the magnetic field. Without the coil, the sensor cannot find the metal object.

Winding the Wire

This step is done by a machine. A worker puts a small plastic spool on the machine. This spool is called a bobbin. Then, the machine takes the thin copper wire. It spins the bobbin very fast. The wire wraps around the bobbin.

This must be perfect. The machine counts the turns. Maybe it needs 200 turns. Maybe it needs 500 turns. It depends on the design. If the machine does 201 turns, the sensor will be wrong. If the wire is loose, the sensor will be weak.

The tension must be just right. If the machine pulls too hard, the wire breaks. If it pulls too soft, the coil is too fat. It will not fit in the housing.

Adding the Ferrite Core

After the wire is wound, we have a coil. But the magnetic field from this coil goes everywhere. We want the field to go forward. We want it to look for the target.

So, we put the coil into a cup. This cup is made of ferrite. Ferrite is a magnetic ceramic material. It looks like dark grey stone. The ferrite cup blocks the magnetic field from the back and sides. It pushes all the energy out the front. This makes the proximity sensor see further.

Soldering the Coil Wires

The ends of the copper wire are very thin. We cannot connect them directly to the main board. They are too fragile. So, workers wrap these thin wires around thicker pins on the bobbin. They dip these pins in hot solder. This makes a strong connection point. Now, the coil assembly is ready.

The Circuit Board Assembly

While one team makes the coils, another team makes the circuit boards. This is called PCB Assembly. The PCB controls the sensor. It sends power to the coil. It listens for changes. It tells the machine to stop.

Applying Solder Paste

We start with a blank green board. We need to put parts on it. But first, we need glue. But this is special glue. It is called solder paste. It is a grey cream made of tiny metal balls and flux.

A machine uses a stencil to put the paste on the board. The stencil is a metal sheet with holes. The paste goes through the holes and lands on the copper pads. It is like screen printing a T-shirt, but with metal paste.

Pick and Place Machine

Now the board goes into a fast robot. This is the Pick and Place machine. The machine has reels of components. It has reels of resistors, capacitors, and chips.

The robot has a small vacuum nozzle. It picks up a tiny part. It moves very fast. It places the part on the wet solder paste. The paste holds the part in place. The robot can place thousands of parts in one hour. It is amazing to watch. It never gets tired. It never shakes.

Reflow Soldering Oven

Now the board has parts, but they are just sitting in wet paste. If you shake the board, the parts fall off. We need to cook it. The board goes into a long oven. This is the reflow oven. The board moves on a conveyor belt. The oven gets hotter and hotter. It reaches about 250 degrees Celsius.

At this temperature, the metal balls in the paste melt. They turn into liquid silver. The flux cleans the copper. Then, the board moves to a cool zone. The liquid metal freezes. Now, the parts are soldered to the board. The connection is permanent.

Automated Optical Inspection (AOI)

We cannot trust the machine blindly. We must check the work. A camera takes a picture of the board. A computer looks at the picture. It checks every solder joint. Is a part missing? Is a part crooked? Is there too little solder? If the computer sees a problem, it stops the line. A human worker checks the board. This ensures every proximity sensor has a perfect brain.

Connecting the System

Now we have a coil and a board. We need to join them. This is often done by hand or by a semi-automatic robot.

Joining Coil to PCB

The worker takes the coil assembly. They place it on the front of the PCB. The pins from the coil go through holes in the board. The worker uses a soldering iron to melt solder on these pins. This is a critical step. The connection must be perfect. The signal from the coil is very small. If the solder joint is bad, the signal will be lost. The sensor will be unstable.

Attaching the Cable

Next, we need a way to get power into the sensor. We also need to get the signal out. So, we attach a cable. The worker takes a long grey or black cable. They strip the end. Inside, there are three colored wires. Brown is for positive power. Blue is for negative power. Black is for the output signal.

The worker solders these three wires to the back of the PCB. They must be careful. The wires must not touch each other. If the brown wire touches the blue wire, it will cause a short circuit. This will break the sensor immediately. Some sensors do not have a cable. They have a connector. This is usually an M12 or M8 connector. The process is the same. The worker solders the connector pins to the board.

Housing and Shielding

The electronics are done. But they are fragile. You cannot put a bare circuit board on a factory machine. Dust and water will kill it. We need to put it in a box. This is the housing assembly phase.

Inserting the Assembly

The worker takes the metal tube (the housing). They put the plastic cap (the sensing face) on the front. Then, they slide the whole electronic assembly inside the tube. It is a tight fit. There is not much space. The worker must push it in gently. They must make sure the coil is right against the front face. If there is a gap, the sensing range will be short.

Adding the Shield

This step is for high-end sensors. Factories are noisy places. There is electrical noise from big motors and drives. This noise can confuse the sensor. To stop this, we add a shield. This is a thin sheet of copper or brass. It goes inside the housing, around the circuit board. It acts like a wall. It stops the outside noise from getting in. It keeps the proximity sensor calm and accurate.

Strain Relief

If you pull on the cable, you might rip the wires off the board. We need to stop this. We put a small plastic piece where the cable enters the housing. This is the strain relief. It grabs the cable tightly. When you pull the cable, the plastic holds it. The force does not reach the solder joints.

Potting

At this point, the sensor looks finished. But it is full of air. Air is bad. Air has moisture. Also, air does not support the parts. If you drop the sensor, the parts will break. We need to fill the air space with solid plastic. This process is called potting.

The Vacuum Chamber

We put the sensors in a rack. They stand up straight. We put the rack in a special machine. This machine mixes the epoxy resin. The resin has two parts. Part A and Part B. When you mix them, they get hard. The machine injects this liquid mix into the back of the sensor.

But we have a problem. There are tiny bubbles in the liquid. These bubbles are bad. So, we do this in a vacuum chamber. The machine sucks all the air out of the room. This pulls the air out of the sensor. The liquid resin flows into every tiny crack. It goes under the chips. It goes around the coil. It fills the sensor completely.

Curing the Resin

The sensors are now full of liquid. We need to make it hard. We put the rack in a big oven. This is not the hot reflow oven. This is a curing oven. It is set to a lower temperature, maybe 80 degrees Celsius. The sensors stay there for 4 to 12 hours. The heat helps the chemical reaction. The liquid turns into a hard, black solid.

Now, the proximity sensor is like a rock. You can hit it with a hammer. It will probably survive. You can throw it in water. It will not leak. The electronics are safe inside the block of resin.

Calibration and Tuning

The sensor is built. But is it accurate? Not yet.

Every coil is a little different. Every resistor is a little different. So, every sensor is a little different. One might detect at 3.9mm. Another might detect at 4.1mm. But the customer paid for 4.0mm. We need to fix this.

The Automated Tuning Rig

We place the sensor on a test rig. A precise metal target moves in front of the sensor. The machine powers up the sensor. It measures exactly when the sensor turns on.

If the distance is wrong, the machine adjusts the sensor. In the old days, a human turned a small screw. Today, it is digital. The test machine sends a signal to the chip inside the sensor. It tells the chip to change its sensitivity.

Or, the machine uses a laser. The laser cuts a special resistor on the board. As it cuts, the resistance changes. The sensitivity changes. The machine stops cutting when the range is exactly 4.0mm. This happens in less than a second.

Now, every sensor in the batch is identical.

Quality Control and Testing

We are almost done. But we cannot ship yet. We must prove the sensor works. A bad sensor can stop a car factory for hours. That costs millions of dollars. So, quality control is very strict.

The Burn-In Test

We put the sensors on a big wall. We plug them all in. We turn them on. We leave them there for 24 or 48 hours.

Sometimes, we make the room hot. This is called a "burn-in." Electronic parts usually fail at the very beginning of their life. By running them for 48 hours, we find the weak ones. If a sensor dies during the burn-in, we throw it away. Only the strong sensors survive.

Thermal Shock Test

The sensor might work at room temperature. But will it work in a freezer? Will it work near a hot oven?

We take a sample of sensors. We put them in a chamber. We drop the temperature to -25 degrees Celsius. Then we raise it fast to +70 degrees Celsius. We do this many times. This is thermal shock. The materials expand and shrink. If the design is bad, the sensor will crack. If the potting is bad, the wire will break.

Water and Dust Test (IP Rating)

A proximity sensor usually has an IP67 rating. This means it is dust-tight and waterproof. To test this, we submerge the sensors in a tank of water. We leave them there. Then we take them out and test them. If water got inside, the sensor will fail.

Electromagnetic Compatibility (EMC)

We also test for noise. We zap the sensor with static electricity. We blast it with radio waves. The sensor must not blink. It must stay steady. This ensures that when a welder is used nearby, the sensor does not go crazy.

Finishing Touches

The sensor has passed all tests. It is a good product. Now it needs a label.

Laser Marking

We do not use paper stickers. Oil and water will wash a sticker away. We use a laser. A laser beam burns the writing onto the metal housing.

It writes the brand name. It writes the part number. It draws a small picture of the wiring. This tells the electrician how to connect the brown, blue, and black wires. This mark is permanent. It will never fade.

Packaging

A worker picks up the sensor. They wipe it clean. They look at it one last time. They put two nuts and two washers on the thread. These are for mounting the sensor.

They put the sensor in a plastic bag. They put a folded paper manual in the bag. Then they put the bag in a small cardboard box. They stick a label on the box. Now, the proximity sensor is ready. It goes to the warehouse. From there, it goes to a distributor. And finally, it goes to a machine.

Summary of the Workflow

Let us look at the whole list one more time. Here is the life of a sensor:

1、Design: Planning the circuit and shape.

2、Coil Winding: Wrapping copper wire to make the magnetic head.

3、PCB Assembly: Using robots to solder chips to the board.

4、Assembly: Soldering the coil and cable to the board.

5、Housing: Putting the electronics inside the metal tube.

6、Potting: Filling the tube with vacuum-sealed resin.

7、Tuning: Adjusting the sensor to the perfect distance.

8、Testing: Running the sensor for days to kill weak units.

9、Marking: Laser engraving the part number.

10、Shipping: Boxing it up for the customer.

Why This Process Matters

You might ask, "Why do I need to know this?"

Understanding the manufacturing helps you choose the right product. When you see a cheap sensor, you know what they skipped. Maybe they used cheap wire. Maybe they did not do the burn-in test. Maybe they did not use vacuum potting, so there is air inside.

A cheap sensor saves money today. But it costs money tomorrow. When it fails, your machine stops.

A high-quality proximity sensor costs more because the process is strict. The materials are pure. The testing is long. But when you install it, you can forget about it. It will work for years.

This process transforms simple elements—copper, sand, oil, and steel—into a smart device. It is a mix of heavy machinery and delicate electronics. It is the hidden process that keeps our modern world moving.

Frequently Asked Questions (FAQ)

What is the main difference between making an inductive and capacitive sensor?

The main difference is the head. An inductive proximity sensor uses a coil of wire to find metal. A capacitive sensor uses two metal plates to find anything. The coil winding step is only for inductive sensors. But the PCB assembly, potting, and housing steps are almost the same for both.

Why is the potting resin so important?

The resin is the shield. It stops water from shorting out the circuit. It stops dust. Most importantly, it stops vibration. Machines shake a lot. Without the hard resin, the tiny wires inside the sensor would break from the shaking. The resin makes the sensor one solid block.

How do manufacturers ensure the sensor is waterproof?

They use the vacuum potting method. By removing the air before the resin cures, they ensure there are no gaps. The resin bonds to the metal housing and the cable. This creates a perfect seal. Then, they test samples underwater to be sure.

Can a sensor be repaired if it breaks?

No. Because of the potting step, you cannot open the sensor. The resin is rock hard. If you try to open the metal tube, you will destroy the circuit board inside. If a proximity sensor breaks, you must buy a new one.

How long does it take to make a single sensor?

The assembly time is fast. Robots work quickly. But the process has waiting times. The resin takes hours to cure. The burn-in test takes days. So, a batch of sensors usually takes about 3 to 4 days to go from raw parts to a finished box.

Why do some sensors have a metal face and others have plastic?

Standard inductive sensors need a plastic face because metal blocks the magnetic field. However, there are special "full metal" sensors. These use a specific type of steel and a different frequency that allows the field to pass through. These are harder to manufacture and cost more, but they are very strong.

What is the "sensing range" and how is it set?

The sensing range is how far the sensor can see the target. It is determined by the size of the coil and the ferrite core. A bigger coil sees further. During manufacturing, the tuning machine adjusts the circuit to make sure the range is precise for that specific size.