Reasons why the sensor may be damaged

A sensor can get damaged. This is a very common problem. It is also a very frustrating problem. A sensor can get damaged for many reasons. Sometimes the reason is simple. Sometimes the reason is complex. As an expert, I have seen many of these problems. A lot of the time, the damage to a sensor is not a mystery. We will look at some common reasons why a sensor gets damaged.

Common Causes of Sensor Damage

A sensor can get damaged for many reasons. These reasons can be put into different groups. Each type of damage can make a sensor stop working. When we know these reasons, we can better use and protect a sensor.

Physical Damage

A sensor is often very fragile. It can get physical damage easily. For example, you drop a device on the ground. The sensor might break. Or, during installation, you do not handle it well. The sensor might get squeezed or bent. This will cause the sensor to be damaged. A sensor has many small parts inside. These parts can easily crack or change shape from outside force. When these parts are damaged, the sensor can no longer work correctly. So, when you install and use a sensor, you must be very careful.

Environmental Issues

A sensor usually works in a specific environment. If the environment is bad, the sensor will get damaged. Here are some common environmental problems.

High and Low Temperatures

A sensor has a temperature range for working. If the temperature is too high, the electronic parts inside the sensor will overheat. Overheating will damage these parts. For example, some sensors have a plastic case that can melt from high heat. The inside circuits of some sensors can burn out from getting too hot. If the temperature is too low, the liquid or parts inside the sensor may freeze or get hard. This will also make the sensor unable to work. So, a sensor must work in the right temperature range.

Moisture and Chemicals

Moisture and water can get inside a sensor. Water can cause a short circuit. Water can also make the metal parts inside the sensor rust. This will damage the sensor. Some sensors work in places with chemicals. For example, in a factory. These chemicals may eat away at the sensor's case or its insides. This will also make the sensor get damaged. So, a sensor must have good protection. It must be able to fight off moisture and chemicals.

Electrical Issues

A sensor needs power to work. If the power has a problem, the sensor will get damaged. Here are some common electrical problems.

Over-voltage and Over-current

A sensor needs a specific voltage and current. If the voltage is too high, the sensor's inside circuit will burn out from too much power. This is like giving a cell phone too much voltage to charge. The phone will break. Too much current is the same. Too much current creates too much heat. The heat will burn the sensor. So, a sensor must be connected to the correct power supply.

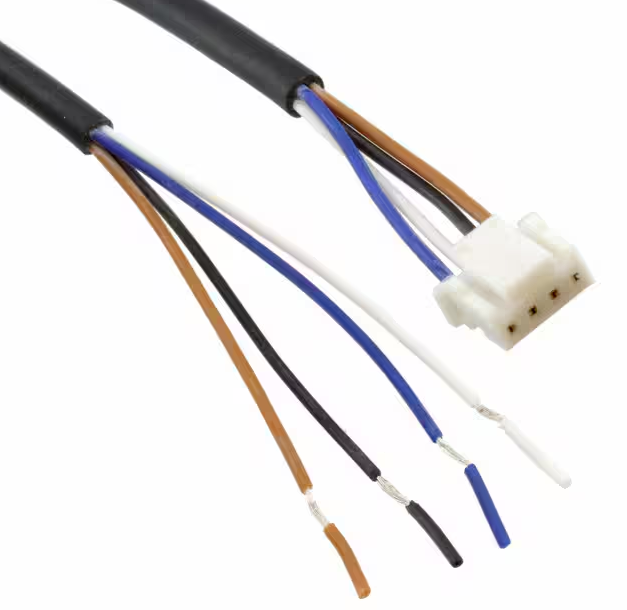

Wrong Wiring

A sensor has many pins. Each pin has a specific job. For example, one pin is for power. Another pin is for ground. If you connect the wires wrong, the sensor will short circuit. This will break the sensor right away. So, when you connect a sensor, you must read the instructions carefully. You must make sure every wire is connected to the right place.

The Relationship Between Knock Sensor Replacement and Damage

A knock sensor is a special sensor. It is usually in a car engine. The job of a knock sensor is to listen to the engine's sound. It listens for a strange "knocking" sound. If it hears one, it tells the car's computer. The car's computer will then change how the engine works. This protects the engine.

Why does a knock sensor get damaged? First, it works in a very bad environment. The engine is very hot. It is also always shaking. These shakes and high heat will slowly damage the knock sensor over time. The special parts inside a knock sensor will stop working from being shaken for a long time. Its case may also crack from the high heat.

Next, the wires of a knock sensor can have problems. The knock sensor's wires can get hard from the high heat. They can get worn out. This will stop the sensor from talking to the car's computer. The sensor will not work correctly.

So, when a knock sensor is broken, you need to do a knock sensor replacement. Knock sensor replacement is taking the old sensor out. Then you put in a new sensor. This process seems simple, but you must be careful. During knock sensor replacement, you must be gentle. You cannot use too much force. You must not damage the new sensor. You also have to make sure all the wires are connected correctly. After a knock sensor replacement, if the problem is gone, then the old sensor was the reason. If the problem is still there, then the sensor was not the reason.

How to Check if a Sensor is Damaged

When a device does not work, how do we know if the sensor is broken? We can check with some methods. This is like a doctor. He must diagnose the patient step-by-step.

First, do a visual check. Look at the sensor closely. See if it has cracks. See if its case is broken. See if its wires are broken or worn. If the sensor has clear physical damage, then it is probably broken.

Second, check the wires. Check the sensor's connecting wires. See if they are connected tight. See if they are loose. If a wire is loose, the sensor cannot work. This may be the simplest problem.

Then, do an electrical check. You can use a multimeter. A multimeter can check voltage, current, and resistance. You can check the sensor's power pins. See if it has the right voltage. You can also check the sensor's signal pins. See if it is sending the right signal. If the sensor does not send a signal, or the signal is not correct, then it might be broken.

Lastly, do a functional test. You can take the sensor out of the device. Then you put in another sensor that you know works. If the device works correctly after the knock sensor replacement, then the old sensor was the problem. This is the most direct way to check.

If you have a car of your own and happen to need a replacement, then please see our Hyundai 3.3 Knock Sensor Replacement Tutorial.

Measures to Prevent Sensor Damage

It is more important to prevent sensor damage than to fix it. Here are some ways to prevent sensor damage.

First, install the sensor correctly. When you install it, do not use too much force. Do not squeeze or bend the sensor. Make sure the sensor is in the right place. If it is not installed correctly, the sensor can be easily damaged.

Second, protect the sensor from its environment. If the sensor works in a place that is wet or has chemicals, make sure it has good protection from water and from being eaten away. For example, use a waterproof case. This can make the sensor last much longer.

Third, make sure the power is stable. A sensor needs stable power. If the power is not stable, the sensor will be affected. This can damage it. So, make sure the power supply connected to the sensor is correct.

Fourth, check on it often. Check the sensor often. See if it has physical damage. See if its wires are normal. If you find a problem, fix it right away. This can stop a small problem from becoming a big one.

Final Thoughts

A sensor gets damaged for many reasons. It can be physical damage. It can be environmental problems, like high heat, wetness, and chemicals. It can also be electrical problems, like too much voltage or wrong wires. When we know these reasons, we can better use a sensor.

When a knock sensor is broken, you must do a knock sensor replacement. This process needs care. A bad knock sensor replacement can damage the new sensor again. So, when you handle any sensor, you must be very careful. To install and use a sensor correctly is the best way to stop it from getting damaged.