Do you know the cost of sensors?

Cost talk first. You may pay from two hundred dollars up to six hundred dollars if you go to a shop. The sensor itself will run thirty to one hundred twenty dollars. Labor makes up the rest. Labor can hit one hundred fifty to four hundred dollars. These numbers can rise if the sensor hides under the intake or under a lot of wires. That is why some owners try the job at home. You can buy the part online for less. You can skip labor cost if you have simple tools and time.

How to determine the signal of a sensor failure

Before that, I hope you can read my article about knock sensor. It told you what a knock sensor does. It sits on the engine block. It listens for ping or knock sounds. When it hears them it sends a small signal to the engine computer. The computer then pulls back timing so the engine stays safe. If the sensor fails the light comes on. You may hear real knock. Power drops. Gas use rises. Codes like P0325 or P0330 show on a scan tool.

How much do sensors cost?

Now let us dig deeper into cost. A small four cylinder car may have the sensor right on top. You can reach it in minutes. Labor stays low. Shops may charge two hundred fifty to three hundred dollars total. A V6 engine may hide the sensor under the intake plenum. The tech must take off the intake, the gasket, and maybe the fuel rail. Labor climbs. Your bill can hit five hundred to six hundred dollars. Trucks with big V8 engines are the same story. The sensor bolts to the side of the block but the intake hides it. That is why you must look up the exact spot for your car before you guess the price.

Parts prices also move. A plain aftermarket sensor may cost thirty dollars. A factory sensor may cost one hundred twenty dollars. Some owners pick the cheap one and it works fine. Others want the same brand the car had from day one. The choice is yours. Either way online stores almost always beat the parts counter at the dealer.

Now you can choose. Pay the shop or do it yourself. If you pick DIY you need time, light, and simple tools. You need a socket set, a ratchet, a torque wrench, and a new sensor. You also need a jack and two stands. You do not need a lift. You can work in a driveway.

How to correctly install the sensor

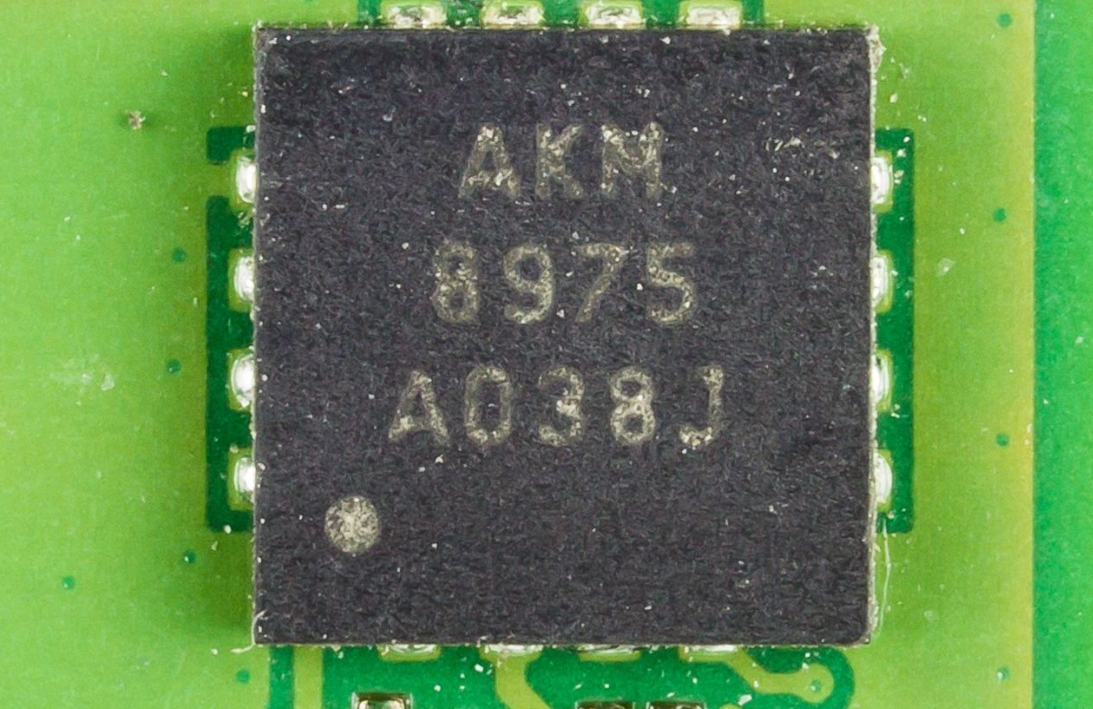

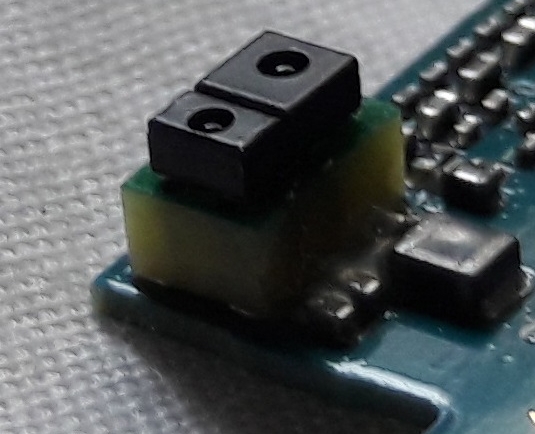

Start the job when the engine is cold. Park on flat ground. Turn the key off. Lift the front of the car and set it on stands. Slide under and look for the sensor. It looks like a fat bolt with a round top and a wire plug. On some cars it sits on the top side of the block. On others it sits under the intake. If you read the first article you already saw pictures. Use those to spot the part fast.

Next step is unplug. Press the small tab on the plug and pull it away. Do not yank the wire. The plug should pop off easy. Now fit the right socket. Most sensors use a 22 mm socket. Turn left to loosen. The bolt comes out in seconds. Keep the bolt in a safe spot. You may need it again if the new sensor does not come with one.

Pull the old sensor straight out. It may feel tight. Twist it a little left and right. It will slide free. Check the hole for dirt. Wipe with a clean rag. Do not let dirt fall inside. Now take the new sensor. Push it into the hole. Thread the bolt by hand first. This keeps the threads safe. Once it feels right use the ratchet. Snug it down but do not over tighten. Look up the spec in the book or on the box. Most call for about 15 to 20 foot pounds. Use a torque wrench so you do not snap the sensor or strip the threads.

Reconnect and test

Plug the wire back. You will hear a small click. That means the lock tab is set. Lower the car. Get in and turn the key. Let the engine idle for two minutes. Watch the dash light. If it stays off you win. If the light is still on hook up a scan tool. Clear the codes. Drive for ten minutes. Watch the light again. If it stays off the job is done.

Some jobs are tougher. If your sensor sits under the intake you must take more steps. Remove the engine cover. Take off the air hose. Mark each hose and wire before you unplug. Unbolt the intake. Lift it off slow. Stuff clean rags in the intake ports so nothing drops inside. Now you can see the knock sensor. Swap it the same way. New gasket for the intake is smart. Old gaskets can leak. Bolt the intake back. Tighten in a cross pattern so the force is even. Hook up every wire and hose. Double check each clip. Start the engine and look for leaks. No leaks means you did it right.

What you need to know about safety and timing

Time talk. A top mount sensor may take fifteen minutes. A hidden sensor may take two hours. Plan half a day if you have never done it. Work slow. Check each step. Keep bolts and clips in a tray so you do not lose them.

Safety talk. Never trust a jack alone. Use good stands. Wear eye wear. Keep hands away from hot parts. If you smell fuel after the job stop the engine and check for leaks.

Summarize

Now you know cost and steps. You also know why the sensor matters thanks to the first article. You can save hundreds if you do the job at home. You can also pick a fair shop if you do not have time. Either way your engine will run smooth again.