What is a camshaft position sensor?

The camshaft position sensor (CMP) is a tiny electronic component that plays a crucial role in the engine of your vehicle. Consider it an important source of information for the Engine Control Unit (ECU), the engine's primary computer. The primary responsibility of the sensor is to inform the ECU of the camshaft's precise rotational position.

Because the camshaft regulates the engine's valves, which allow the air-fuel mixture to enter and the exhaust gases to exit, this information is essential. The ECU can precisely time two crucial events by knowing the position of the camshaft. In order to ensure efficient burning, it first regulates fuel injection, ensuring that fuel is sprayed at the exact moment. Secondly, it controls spark ignition, igniting the fuel by precisely timing the spark plugs. To put it briefly, the camshaft position sensor makes it possible for the engine to operate smoothly, powerfully, and effectively.

How It Functions with Other Engine Components

Two other important components—the crankshaft and the camshaft—should be understood in order to comprehend the function of the camshaft sensor.

The crankshaft and the pistons are attached. The fuel ignites the pistons, which rise and fall to turn the crankshaft. After a while, the crankshaft's rotation powers the wheels, and the ECU gets data from its sensor regarding the positions of the pistons.

An engine's intake and exhaust valves are opened and closed by the camshaft, a rod with lobes, or bumps. A timing belt or chain connects it to the crankshaft, and it always rotates at precisely half the crankshaft speed.

Both a crankshaft sensor and a camshaft sensor provide data to the ECU. The ECU is notified by the crankshaft sensor when a piston reaches the top of its cylinder, but it is unable to determine which of the four engine strokes—exhaust, power, compression, and intake—the piston is on. The camshaft sensor can help with that. Since the camshaft regulates the valves, the ECU can determine which stroke is occurring based on its position. This enables the ECU to recognize which cylinder the spark plug should be fired into and inject fuel into. The engine's timing is flawless thanks to this teamwork.

Different Camshaft Position Sensor Types

There are two main types of camshaft position sensors used in modern cars.

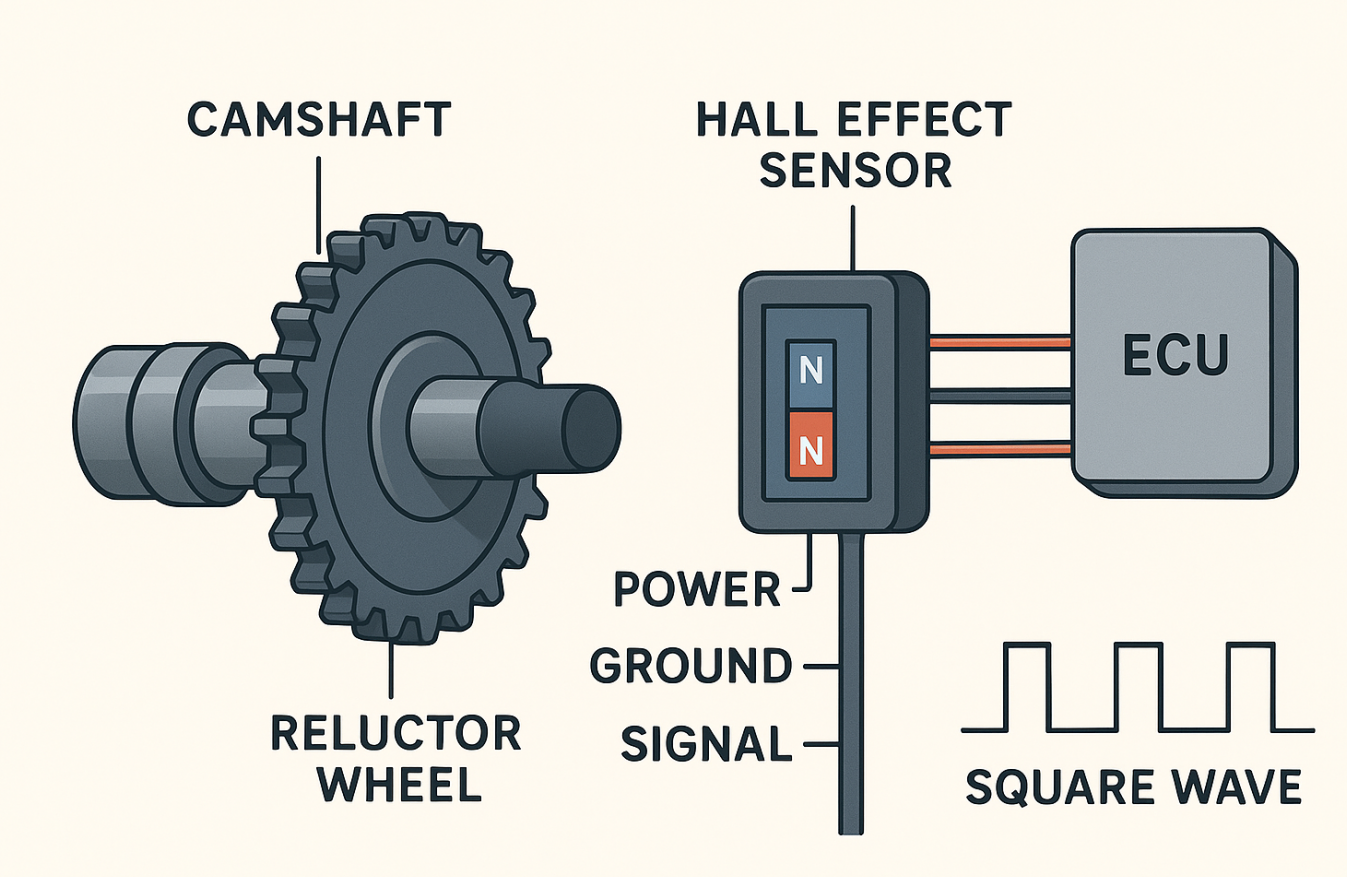

Hall Effect Sensor

The most prevalent kind is this one. Being an "active" sensor, it requires a tiny amount of power from the vehicle's battery in order to function. It detects teeth on a rotating "trigger wheel" that is fastened to the camshaft using a magnet and a Hall effect element.

The sensor produces a clear, digital square wave signal (on/off) when each tooth passes through it, disrupting the magnetic field. Even at low engine speeds, such as when you're starting the car, this signal is incredibly precise and clear.

Magnetic Sensor (Variable Reluctance)

This sensor is "passive," which means it doesn't require an external power source because it produces its own electricity. It is made up of a permanent magnet and a coil of wire.

A voltage is induced in the wire coil as a result of the trigger wheel's teeth changing the magnetic field as they pass by. An analog sine wave signal is produced as a result. The signal gets stronger as the camshaft spins faster. These sensors are straightforward and robust, but at very low RPMs, they may only generate a weak signal.

Important Roles in Engine Management

The information obtained from the camshaft position sensor is essential for several crucial engine functions. In modern engines, it allows for sequential fuel injection, where fuel is injected into each cylinder independently just before the intake valve opens. The CMP tells the ECU which cylinder is on its intake stroke to guarantee accurate fuel delivery, which improves fuel economy and reduces emissions.

Accurate ignition timing is also guaranteed by the sensor. By verifying that a cylinder is on its compression stroke, it enables the ECU to fire the spark plug at the ideal time for maximum power and to avoid damaging engine knock.

In engines with Variable Valve Timing (VVT), the ECU can adjust when the valves open and close to optimize performance. The CMP provides the feedback the ECU needs to monitor and control these adjustments accurately.

Finally, it is essential for engine diagnostics. The ECU constantly compares the camshaft and crankshaft signals. If they don't match up, it can detect a problem like an engine misfire and identify which cylinder is at fault. It will then turn on the Check Engine Light and store a diagnostic trouble code (like P0340) to help a mechanic pinpoint the issue.

For information on 3.3 knock sensor replacement, please read our article: https://www.joydo-ele.com/article/news/hyundai-3-3-knock-sensor-replacement-tutorial.html

Common Camshaft Position Sensor Problems

Though reliable, camshaft position sensors can fail due to the engine's heat and vibration. When one fails, you'll likely notice some clear signs.

Signs of a Problem

The engine may crank but not turn over, or you may have trouble starting it. Additionally, the engine may stall without warning, particularly after warming up. Additionally, you might encounter a rough idle and subpar performance, which could make the car feel jerky, slow to accelerate, or powerless. Reduced fuel economy is another typical symptom, as improper timing lowers engine combustion efficiency. The dashboard's "Check Engine" light, which turns on when the engine control unit (ECU) detects an issue, is frequently the first and most noticeable indicator.

Reasons for Failure

A sensor may malfunction for a number of reasons. The most frequent is simple heat damage, in which the internal electronics of the sensor deteriorate after years of exposure to high engine temperatures. The frayed, corroded, or damaged wires that lead to the sensor may also be the cause. An internal short can occasionally be caused by the sensor's electronics simply wearing out. Rarely, a malfunction may result from mechanical damage to the camshaft's trigger wheel, which could send the wrong signal.

For reasons why the sensor may be damaged, please read : https://www.joydo-ele.com/article/news/reasons-why-the-sensor-may-be-damaged.html