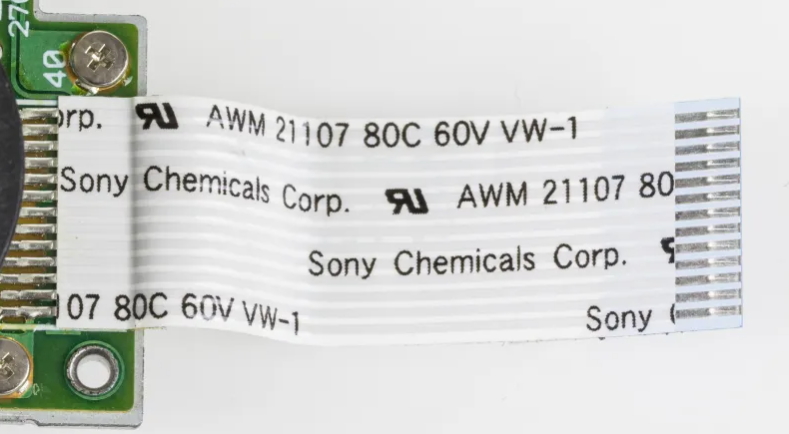

What are Flat Flexible Cables?

Flat Flexible Cables, or FFCs, are a kind of electrical cable used in many devices. They have flat and thin wires placed side by side in a ribbon shape. It can bend and move, so they fit well in small spaces or in parts that move a lot. Many modern devices need them, from consumer gadgets to machines in cars and hospitals.

If we look at how electronics work today, FFCs are very important. They do not only link small parts inside phones and laptops, but they also help in cars with sensors like the knock sensor. These cables make sure signals move in a safe and stable way. It connect well with PCBs and give engineers a reliable option for compact design.

The Basic Structure of FFCs

The design of FFCs is simple. Wires run in a flat line and are covered with a thin plastic layer. This layer protects the wires and lets the cable bend. Because the wires stay in a line, the signals they carry stay stable.

If we compare them with round wires, we see the flat shape saves space and lowers noise. The cable is also lighter, and signals travel in a more steady way. In PCB design, this makes them useful for high-speed work.

In cars, the design is even more helpful. A knock sensor needs clear data transfer. With an FFC, the sensor can send data to the control unit without extra bulk.

How FFCs Differ from Other Cable Types

Some people think FFCs are the same as FPCs, but they are not. FFCs are simple, with straight wires and a cover. FPCs are more complex. They can have many layers and even carry parts like resistors.

Another point is size and use. FFCs are easy to buy in standard forms. They come in fixed sizes, with set pins and lengths. That makes them easy to match with PCB connectors. FPCs are mostly made for one special job.So, if you only need to link a display to a PCB, FFCs can do it. If you need more complex circuits, FPCs may be better.

Applications of FFCs in Electronics

We can see FFCs in many common devices. In laptops, they link the keyboard and the board. In phones, they connect displays, cameras, and power parts. In printers, they link moving parts with control units.

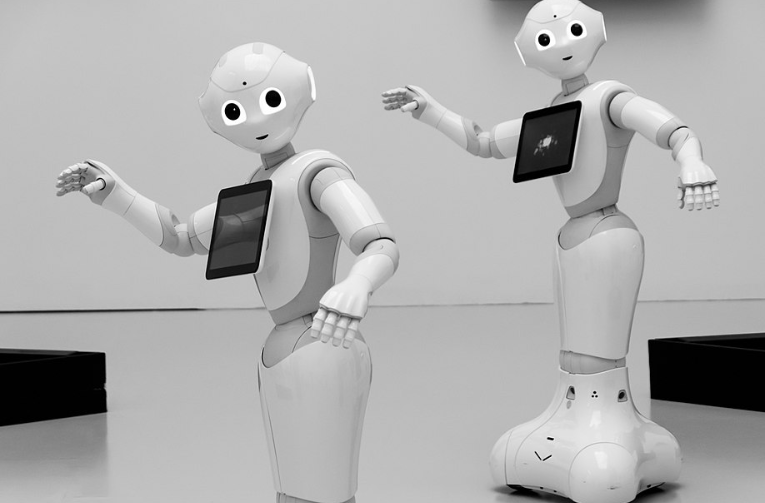

Cars also use them more and more. They link control modules with sensors, like the knock sensor or oxygen sensor. Because space in an engine is tight, the flat cable makes sense. It saves room and keeps the signal clean.In medical tools, they also work well. Machines like ultrasound need light and safe parts, and FFCs are good for that. In robots, the cable can bend often and still last.

Integration of FFCs with PCB Design

One main strength of FFCs is how well they fit with PCBs. Most PCBs already have connectors that match the cable. That means no soldering is needed, which saves time and avoids errors.

For example, in a phone or tablet, the screen links to the main PCB through an FFC. This makes the build simple and neat. In large machines, FFCs help connect sensors to the board, so the data flow stays smooth.In cars, this is even more clear. A knock sensor must send signals to the ECU without noise. FFCs give that safe and direct path.

Advantages of Using FFCs

FFCs have many good points. They save space and light. It can bend without breaking. Their flat wires lower noise better than round ones. They are easy to use, since many connectors are made for them.

They also last long in moving parts. In laptops or printers, it can bend again and again. They are cheap to make, and the quality is steady.In engine parts like the knock sensor, this is a big plus. If a cable fails, the data will not go through right. That may hurt the engine. FFCs lower this risk.

Challenges in Using FFCs

Still, FFCs are not perfect. They can break if bent too much. Their flat body makes them easier to damage than round wires. They must be put in with care.There is also the problem of fit. Many devices use standard forms, but if you need a special type, the cost goes up. In places with high heat, the cable must use better cover material to last.In cars, this is very true. A knock sensor sits near the engine, where heat and shake are high. If the wrong cable is used, it may fail fast.

Future Trends in FFC Technology

As devices get smaller, the need for flat and safe cables will grow. FFCs will be part of that. New materials and new designs will make them stronger and more steady.There may also be more mix of FFCs and FPCs. This will give the best of both worlds, simple use and more functions. Robots, wearables, and car parts will need this.For sensors, like the knock sensor, new FFCs will handle faster data and more stress. They will be key in smart cars and other systems that need fast and safe control.

Conclusion

FFCs are simple, but they play a big role in electronics. They are flat, light, and easy to use. They save space and give steady signals. That is why they are in so many devices, from phones to cars.

They fit well with PCBs, and they work with sensors like the knock sensor. They are not free from limits, but they give a strong balance of cost, use, and safety.As time goes on, FFCs will stay in use. They will grow better with new tech. It will still be key in cars, medical tools, and robots. It may be simple in shape, but they are vital in modern design.