Thermocouple vs. RTD: Which Temperature Sensor Suits Your Needs?

Accurate temperature measurement is one of the most important tasks in modern industry. Many processes depend on correct temperature data. This includes process control in chemical plants. It includes research in laboratories. It includes simple HVAC systems in buildings. Getting the temperature wrong can lead to bad product quality. It can cause unsafe conditions. It can waste a lot of energy. This is why the choice of the temperature sensor is a critical decision.

The two most common industrial temperature sensors are thermocouples and RTDs. Both devices are used to measure temperature. But they work in very different ways. They have very different strengths. They also have very different weaknesses. A thermocouple might be perfect for a steel furnace. But it might be a bad choice for a pharmaceutical lab. An RTD might be perfect for that lab. But it would be quickly destroyed in the furnace.

What is a Thermocouple and How Does It Work?

A thermocouple is a very common type of temperature sensor. It is simple. It is tough. It is based on a basic principle of physics. It does not measure temperature directly. Instead, it measures a change in voltage. This voltage change is directly related to the temperature.

The Seebeck Effect: The Foundation of Thermocouple Operation A thermocouple works because of the Seebeck effect. This principle is simple. When two different types of metal wires are joined together at one end, they create a circuit. If one end of this circuit is heated, a small voltage is created. This voltage is measured in millivolts. The amount of voltage produced depends on the temperature difference between the two ends.

This temperature sensor has two junctions. The first is the hot junction. This is the end that is placed at the point of measurement. This is the end that gets hot or cold. The second is the cold junction. This is the reference point. The voltage produced by the thermocouple tells us the temperature difference between the hot junction and the cold junction. To find the actual temperature at the hot junction, we must know the temperature at the cold junction. This is a very important part of using a thermocouple.

Key Advantages of Thermocouples

Thermocouples are popular for many good reasons. Their advantages make them the only choice for certain jobs. First, they have a very wide temperature range. Different types of thermocouples use different metal pairs. Some types, like Type K or Type N, can measure temperatures well over 1000 degrees Celsius. Special types, like Type R or Type S, can be used in furnaces up to 2300 degrees Celsius. This is much higher than most other sensors can handle. Second, they have a fast response time.

The hot junction of a thermocouple can be made very small. It can even be an exposed wire. Because it has very low mass, it heats up and cools down very quickly. This fast response time is critical for applications where temperatures change rapidly. Third, thermocouples are very rugged and durable. They are often just two metal wires inside a protective metal tube. This simple design makes them very resistant to vibration and physical shock. They can be used in harsh industrial environments.

It will last a long time. Fourth, they are self-powered. The Seebeck effect creates its own voltage. This means the temperature sensor does not need an external power supply or excitation current to work. This simplifies the circuit design. Fifth, they generally have a lower initial cost.

A simple thermocouple sensor is often cheaper to buy than an RTD sensor. This makes them a good choice when many sensors are needed for basic monitoring. Sixth, they have a small size and flexible configurations. The sensor itself can be just the tip of two wires. This allows them to be placed in very small or tight spaces.

Limitations and Challenges of Thermocouples

Despite their ruggedness, thermocouples face several critical limitations that make them unsuitable for applications demanding high precision.

A primary challenge lies in the signal quality and processing. The thermocouple output is inherently non-linear, meaning the voltage change is not consistent across the temperature range. This results in lower absolute accuracy compared to RTDs and requires the measurement device to perform complex linearization using built-in tables or formulas. Furthermore, the signal itself is a very small millivolt signal, making it highly susceptible to electrical noise from motors or power lines, thus requiring careful shielding and wiring practices.

Another fundamental challenge stems from the sensor's operating principle: it measures a temperature difference, not the absolute temperature. This means the system must include Cold Junction Compensation (CJC) to monitor the reference point, which adds both complexity and a potential source of error to the measurement system.

Finally, thermocouples can struggle with long-term reliability. When used at very high temperatures, the metal wires are prone to drift over time due to degradation. This requires more frequent checking and calibration to ensure the readings remain reliable.

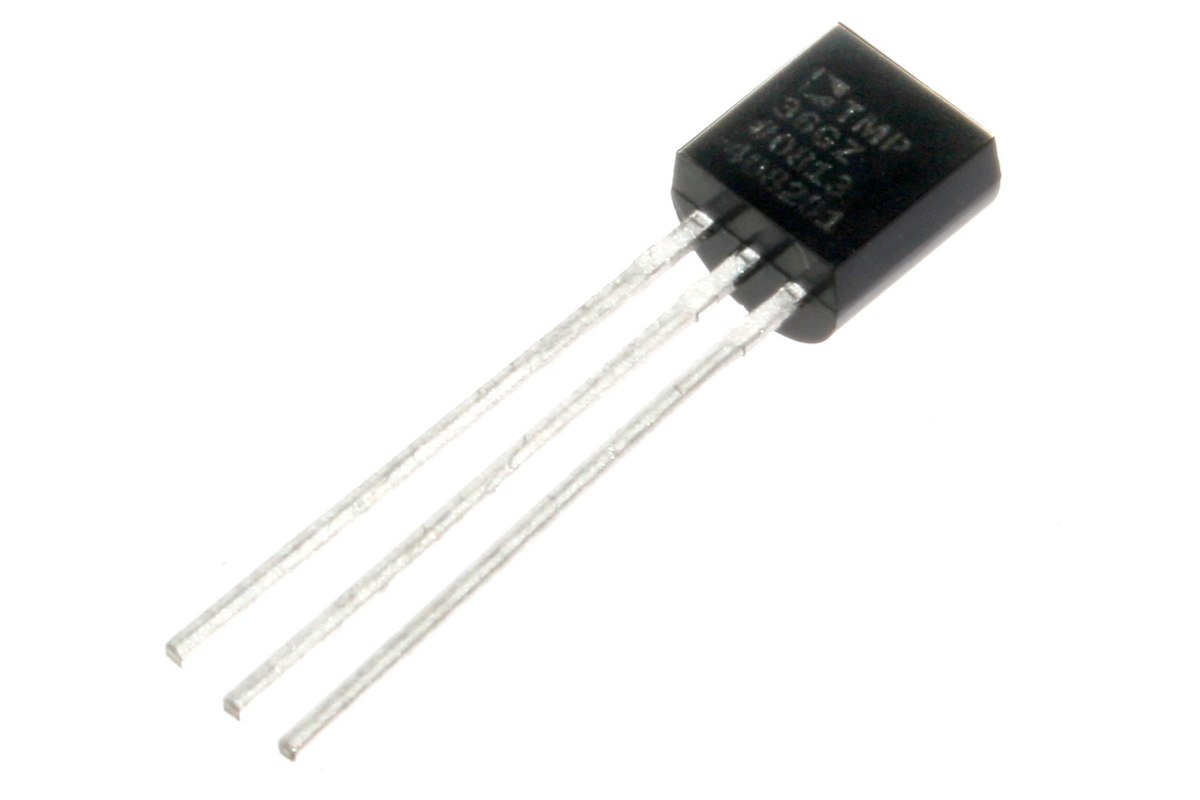

Resistance Temperature Detector (RTD) Principle

What is an RTD and How Does It Work?

An RTD, or Resistance Temperature Detector, is the other major type of temperature sensor. It is known for its high accuracy. It works on a different principle than a thermocouple. An RTD is a sensor whose resistance changes with temperature.

Resistance-Temperature Relationship: The Core of RTD Operation An RTD works on a simple principle. The electrical resistance of a pure metal changes in a very predictable way with temperature. As the metal gets hotter, its resistance goes up. As it gets colder, its resistance goes down. RTDs are usually made from platinum. Platinum is a very stable metal. Its resistance change is very well understood. This makes it a perfect material for a high-accuracy temperature sensor. The most common type of RTD is the Pt100. This means it is made of platinum (Pt). It has a resistance of 100 ohms at 0 degrees Celsius.

Another common type is the Pt1000. It has a resistance of 1000 ohms at 0 degrees Celsius. To measure the temperature, a small, constant current is passed through the RTD element. The measurement device then reads the voltage across the RTD. By knowing the current and the voltage, the device can calculate the RTD's resistance. This resistance is then converted into a very accurate temperature measurement. This is often done using a circuit like a Wheatstone bridge.

Key Advantages of RTDs

The defining characteristics of RTDs are their high absolute accuracy and excellent repeatability, often achieving precision within a fraction of a degree. This makes them indispensable in scientific laboratories and processes that require exact temperature control.

This precision is supported by the superior linearity of their output signal. Since platinum's electrical resistance changes in a highly predictable, straight-line manner with temperature, the conversion from a resistance reading to a temperature is significantly simpler than the processing required for a thermocouple.

In terms of operational and system benefits, RTDs offer high stability and low drift over extended periods. Because the noble metal platinum degrades slowly, the sensor remains true to its original calibration for many years, resulting in less maintenance. Furthermore, the measurement system is simpler because RTDs measure absolute resistance, meaning they do not require Cold Junction Compensation (CJC). Finally, their use of a larger, resistance-based signal makes them less susceptible to electrical noise from nearby motors and power lines.

Limitations and Challenges of RTDs

While RTDs are champions of precision, they are constrained by factors relating to operational limits and physical durability.

The most significant operational limits involve temperature and speed. RTDs have a limited temperature range, typically rated only up to about 600 degrees Celsius This prevents their use in high-temperature industrial environments like furnaces, where a thermocouple would be required. Dynamically, the sensor exhibits a slower response time. Because the platinum element is encased within a protective body, its larger thermal mass means it takes longer to heat up or cool down, making it unsuitable for measuring very fast temperature fluctuations.

From a system design perspective, RTDs are passive devices(This refers to components such as capacitorsand resistors.) and require an excitation current to work. This current can generate a small amount of heat in the sensor itself—known as self-heating—which introduces a potential error in the temperature measurement if not correctly managed.

Finally, physical challenges and cost are factors. RTDs are more fragile than thermocouples; the delicate platinum coil is susceptible to damage from strong vibration or physical shock. They also tend to have a larger physical size, which can complicate installation in very tight spaces. Coupled with the use of expensive pure platinum and complex manufacturing, RTDs also carry a higher initial cost per sensor.

Direct Comparison: Thermocouple vs. RTD (The Decision Matrix)

Thermocouple vs. RTD: A Side-by-Side Comparison

Choosing between these two sensors means trading off their advantages. A direct comparison highlights their fundamental trade-offs, which stem from their core operating principles: the thermocouple uses the Seebeck effect to generate a voltage, while the RTD relies on a predictable change in resistance.

This core difference dictates their performance. The RTD is the clear winner in precision. It offers high accuracy, excellent repeatability, and a superior linear signal, making its resistance output easy to read and highly stable with low drift over time. In contrast, the thermocouple is generally less accurate and has a non-linear output that requires signal conditioning. It is also more prone to drifting from its calibration, especially at high temperatures.

However, the thermocouple excels in range and durability. It boasts a massive operating range (from below -200°C to over 2300°C), far exceeding the RTD's more limited range (typically -200°C to 600°C). The thermocouple's simple, low-mass junction gives it a much faster response time and makes it highly rugged and resistant to vibration and shock. The RTD, with its larger sensing element, is slower to respond and more fragile.

From a system perspective, the thermocouple is self-powered and needs no excitation, but it requires complex Cold Junction Compensation (CJC) to get an absolute reading. The RTD needs no CJC but does require an excitation current, which can cause minor self-heating errors. Furthermore, the thermocouple's tiny millivolt signal is weak and susceptible to electrical noise, while the RTD's resistance-based signal is stronger and less affected. Finally, a basic thermocouple is smaller and has a lower initial cost compared to the more expensive RTD sensor.

When to Choose Which: Matching Sensor to Application Needs

Making the Right Choice: Application-Specific Scenarios

The best temperature sensor is the one that fits your job. You must look at your needs. You must then match them to the sensor's strengths.

Choose a Thermocouple When: You should choose a thermocouple for several situations. Choose a thermocouple when your application demands very high temperatures. If you need to measure the temperature of a furnace, an engine exhaust, or molten metal, you must use a thermocouple. An RTD will be destroyed at these temperatures.

This is any temperature above 600 degrees Celsius. Choose a thermocouple when fast response to temperature changes is paramount. If you are controlling a process where the temperature spikes up or down quickly, you need a sensor that can keep up. The fast response time of an exposed junction thermocouple is perfect for this. Choose a thermocouple when the environment is harsh. If the sensor will be exposed to high vibration, like on a large machine, or heavy physical shock, you need a rugged sensor. The simple, solid design of a thermocouple makes it the ideal choice.

Choose a thermocouple when a small, flexible sensor is required. The sensor tip can be very small. It can be bent to fit into tight spaces. Choose a thermocouple when cost-effectiveness is a primary driver. If you need to measure temperature at many points for basic monitoring, and high accuracy is not the most important thing, the lower cost of thermocouples is a big benefit.

Choose an RTD When: You should choose an RTD for a different set of situations. Choose an RTD when high accuracy, precision, and repeatability are critical. This includes applications like laboratories, pharmaceutical production, and food and beverage processing. In these jobs, a change of half a degree matters. The high accuracy of an RTD is necessary. Choose an RTD when the temperature range is moderate.

If your process stays between -200 degrees Celsius and 600 degrees Celsius, an RTD will work perfectly. This range covers most chemical processes, ovens, and climate control systems. Choose an RTD when long-term stability and minimal drift are essential. If the sensor will be installed for many years, you need it to stay accurate. An RTD will not drift much. This saves money on calibration and maintenance. Choose an RTD when linear output is preferred.

A linear signal is easier for control systems to process. It simplifies the programming and calculations. Choose an RTD when no Cold Junction Compensation is desired. The RTD circuit is simpler. It does not need to measure the reference temperature. This can make the overall system design easier. Choose an RTD when lower susceptibility to electrical noise is required. In a factory with a lot of large motors, the RTD's stronger signal will be more reliable.

Advanced Considerations for Sensor Selection

Beyond the Basics: Further Factors in Your Decision

After you choose between a thermocouple and an RTD, there are still more choices to make. These factors also affect your temperature measurement.

Specific Sensor Types Even within each category, there are many types. For thermocouples, you must choose the metal type. A Type K thermocouple is very common. It has a wide range. A Type J thermocouple is also common. It has a smaller range but is good for certain atmospheres. A Type T is very stable at low temperatures. For RTDs, you must choose the resistance. A Pt100 RTD has 100 ohms at 0 degrees Celsius. It is the most common standard. A Pt1000 RTD has 1000 ohms. It is better for battery-powered devices because it uses less excitation current. It also has less error from wire resistance.

Wiring Configurations Wiring is very important for RTD accuracy. An RTD measures resistance. But the long wires connecting the RTD to the measurement device also have resistance. This wire resistance adds to the sensor's resistance. This causes an error in the temperature reading. A 2-wire RTD configuration is the simplest. But it is the least accurate. It cannot remove the wire resistance error. A 3-wire RTD configuration is the most common in industry.

It uses a third wire. This third wire allows the measurement device to measure the wire resistance. It can then subtract this error from the reading. This makes it much more accurate. A 4-wire RTD configuration is the most accurate. It is used in laboratories. It uses two wires to carry the excitation current. It uses two different wires to measure the voltage. This method completely removes all error from the wire resistance.

Signal Conditioning and Transmitters The raw signal from a temperature sensor is usually not sent a long distance. The thermocouple signal is too small. The RTD resistance signal is not standard. So, a signal conditioner or transmitter is often used. This small device is placed near the sensor. It converts the sensor's signal into a standard industrial signal. The most common standard is a 4-20mA current loop. This 4-20mA signal is very strong. It is not affected by noise. It can be sent over very long wires. The transmitter also handles the linearization for thermocouples. It handles the cold junction compensation. This makes the control system's job much easier.

Environmental Factors The operating environment is very important. The sensor is protected by a metal tube called a sheath. The material of this sheath must be compatible with the environment. If you are measuring a strong acid, you need a sheath that will not dissolve. If the pressure is very high, the sheath must be strong enough to not be crushed. If there is a lot of electromagnetic interference (EMI), the wires must be shielded correctly.

Conclusion

There is no single "better" temperature sensor. A thermocouple is not better than an RTD. An RTD is not better than a thermocouple. The best sensor is the one that is right for your specific needs. It is all about the application fit. We can summarize the key points. A thermocouple is the choice for very high temperatures. It is the choice for fast response times. It is the choice for high-vibration environments. An RTD is the choice for high accuracy. It is the choice for high stability. It is the choice for a moderate temperature range where precision is the most important goal. You must evaluate all your application requirements. You must know your temperature range. You must know your accuracy needs. You must understand your environment. You must consider your budget. You must know how fast your response time needs to be. When you have this information, you can make an informed decision.

Need help selecting the perfect temperature sensor? Contact our experts today! Explore our comprehensive range of Thermocouples and RTDs.