Step-Down Transformers: The Last Mile of Power Delivery

An electrical device called a step down transformer is designed to reduce voltage from a higher value on the primary winding to a lower value on the secondary winding. It is the last and most common kind of transformer in the power distribution system, directly ensuring that end users receive ac electricity in a safe and effective manner. While step down transformers reduce voltage, a step-up transformer performs the opposite function of increasing voltage, typically used at power plants to boost voltage for long-distance transmission on transmission lines.

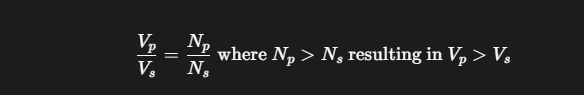

Fundamental Idea: The turns ratio controls the operation. The secondary winding's (Ns) number of turns is substantially lower than the primary winding's (Np) number in a step-down configuration. This winding ratio is crucial for step voltage transformation in alternating current systems.

To maintain constant power (P=V * I), the current is proportionately increased as the voltage is decreased, ignoring losses. End-user devices are designed to run at low voltages (such as 120V or 240V), but they still need enough load current to power the equipment, so this increase in current is required. Transformer voltage regulation ensures that the secondary voltage remains stable under varying load conditions.

Classification by Application and Mounting

Step down transformers are generally classified as Distribution Transformers, varying mainly by their installation location and the voltage levels they handle.

Substation Transformers (Primary Step-Down)

These sizable, utility-grade units are found close to consumption areas in significant substations. By converting sub-transmission voltages (like 138 kV or 69 kV) to local distribution feeder voltages (like 13.8 kV or 4.16 kV), they carry out the first significant step-down function in the power transmission process.

Design: Because of the heavy loads they handle, these big, oil-filled units frequently use forced-air (ONAF) or forced-oil (OFAF) cooling. The transformer core is designed to minimize losses while handling high primary voltage and current.

Winding Configuration: They often use a Wye (Star) connection on the secondary side to supply phase-to-phase and phase-to-neutral voltages, providing flexibility for distribution in both residential and industrial applications. The vector grouping of these transformers is crucial for maintaining proper phase relationships.

Pole-Mounted Transformers

These are the most commonly seen step down transformers in rural areas and older urban neighborhoods. They are affixed to utility poles. Their purpose is to lower the primary distribution line voltage (for example, 13.8 kV) to the typical consumer service voltage (240/120V split-phase).

Design: Usually filled with oil, they have capacities ranging from 10 kVA to 500 kVA. Their dimensions are ideal for a small group of homes' distributed load. The magnetic core of these transformers is optimized for efficiency in this voltage range. Transformer sizing is critical to ensure adequate capacity for the served area.

Pad-Mounted Transformers

These units, which are installed on concrete pads at ground level and are kept safe in a metal cabinet that is impenetrable, are frequently found in modern subdivisions and commercial spaces.

Function: Made for underground cable feeds, but identical to pole-mounted units. For local services, they reduce the distribution voltage, playing a crucial role in power distribution to end-users.

Safety and Aesthetics: The enclosed design gives maintenance workers easy access and is a safer, more attractive substitute for overhead lines. This design also helps protect against voltage drop due to environmental factors and prevents unauthorized back feeding or reverse feeding.

Key Design Features Specific to Step-Down Units

While all transformers share core principles, distribution (step-down) units have unique design considerations focused on the final leg of power delivery in electrical circuits.

Voltage Regulation and Loading Profile

Unlike large power transformers which operate near full load, distribution transformers often experience highly variable loads throughout the day (low load at night, high load during the evening peak).

Regulation: They must maintain tight transformer regulation at the secondary terminals to ensure consistent power quality for consumers, even as load fluctuates. This is crucial for maintaining stable voltage levels in residential and industrial applications. Voltage adjustment mechanisms, such as voltage taps, are often incorporated to fine-tune the output voltage.

No-Load Losses: Because they are energized 24/7, they are designed to minimize No-Load Losses (Core Losses). This is achieved by using high-quality Grain-Oriented Electrical Steel (GOES) and optimizing the transformer core design. The no-load voltage is carefully controlled to ensure efficient operation even during periods of low demand.

Secondary Winding and Bushings

Low-Voltage Side: The secondary windings carry high currents at low voltage. Therefore, the secondary conductors are typically very thick (often foil or heavy bar copper) to minimize resistance (I^2R) losses and manage load current effectively. These copper losses are a significant factor in transformer efficiency.

Neutral Terminal: Distribution transformers usually feature an external neutral terminal that is solidly grounded. This neutral is crucial for providing the split-phase or three-phase service necessary for most homes and businesses, allowing for different voltage levels within the same system.

Isolation and Safety Features

The proximity of step down transformers to the public requires enhanced safety measures, especially in residential neighborhoods.

Fuses and Breakers: External primary current-limiting fuses or circuit breakers are installed to protect the transformer from severe overcurrents or internal faults. This is essential for maintaining code compliance and electrical safety.

Pressure Relief: Pad-mounted units often include a pressure relief device that vents internal pressure (caused by fault conditions) to prevent catastrophic tank rupture. This is a critical safety feature for transformers in public areas.

Real-World Applications: Residential and Commercial Services

Step down transformers are the unsung heroes enabling almost every electrical transaction in a community, from powering homes to supporting industrial applications.

Residential Split-Phase Service

In North America, homes typically use single-phase transformer configurations for 240/120 V service. The step-down transformer provides this using a secondary winding that is center-tapped.

240 V: Used for high-power appliances like ovens, clothes dryers, and central air conditioning units (Phase A to Phase B).

120 V: Used for general lighting, outlets, and small appliances (Phase A or Phase B to the Neutral connection).

Commercial Three-Phase Service

Commercial buildings, apartment complexes, and light industrial facilities typically require three-phase power for large machinery, elevators, and dedicated HVAC systems.

Delta-Wye Connection: A common configuration where the primary side is Delta-connected (three phases) and the secondary is Wye-connected (three phases plus a neutral). This setup efficiently steps down the medium voltage (e.g., 13.8 kV) to a common commercial voltage (e.g., 480/277 V), suitable for various industrial applications. This configuration can accommodate both lagging power factor and leading power factor loads, which are common in commercial settings.

Street Lighting Circuits

Smaller, dedicated step down transformers are used to power street lighting circuits. These units reliably convert the distribution voltage to the required lamp voltage (which may be a few hundred volts) and often utilize photocell sensors to activate based on ambient light levels.

Maintenance and Failure Modes

Because of their high volume and exposure to weather, maintenance protocols for step down transformers focus on accessibility and environmental resilience. Regular inspections by an electrical inspector are crucial for ensuring ongoing safety and efficiency.

Inspection and Environmental Factors

Routine inspections involve checking for external damage (e.g., vehicle impact on pad mounts), rust or corrosion, and clear signage. Environmental factors are a major concern:

Wildlife Intrusion: Squirrels and birds frequently cause external short circuits or damage to bushings, leading to flashovers.

Oil Leaks: Small oil leaks are common in older units; major leaks require immediate service to prevent insulation failure and maintain proper voltage levels.

Overloading: During extreme weather (e.g., hot summers requiring heavy AC use), prolonged overloading accelerates insulation degradation and can lead to excessive voltage drop.

Testing and Diagnosis

Unlike large power transformers that receive frequent DGA, distribution transformers rely more on external visual and electrical tests:

Thermal Imaging: Infrared cameras are used to detect hot spots on the tank, bushings, and connections. A localized hot spot indicates a loose connection or an internal tap changer problem.

Voltage Checks: Technicians regularly check the output voltage to ensure the tap changer is set correctly and the voltage remains within acceptable limits under peak load conditions. This is crucial for maintaining proper transformer voltage regulation.

Lightning Arresters: External lightning arresters, which divert surge currents to the ground, are inspected for physical damage or signs of failure to protect against high voltage surges.

Short-Circuit Test: Periodically, a short-circuit test may be performed to assess the transformer's ability to withstand fault conditions and verify its impedance characteristics.

Transformer Nameplate: Regular verification of the transformer nameplate information ensures that the unit is operating within its designed parameters for voltage, current, and frequency.

Conclusion

The step down transformer is the critical link that translates the large-scale efficiency of the power grid into local, safe, and usable electrical power for consumers. Its presence in substations, on poles, and on pads across every community underscores its role as "the last mile" delivery mechanism in power distribution.

The design emphasizes minimizing core losses (due to 24/7 operation) and maximizing safety and resilience against environmental factors. Proper specification—matching the KVA rating, impedance, and connection type (e.g., Wye vs. Delta)—is essential to ensure a reliable and stable power supply for all end-users, whether in residential neighborhoods or industrial settings.

By efficiently managing voltage levels, current transformation, and power factor, step down transformers play a crucial role in maintaining the integrity and efficiency of our electrical circuits. As we continue to advance in power transmission and distribution technologies, the fundamental principles of these transformers remain at the heart of our electrical infrastructure.