How to Use Transil Diodes for Effective Circuit Protection

You can protect your circuits from damaging voltage spikes by using a diode transil. This special diode reacts instantly to surges, absorbing excess energy before it harms your sensitive components. A diode transil stands out for its speed and reliability, making it essential in devices like smartphones, electric vehicles, industrial machinery, and even solar energy systems. Correct selection and placement give you solid protection and help your electronics last longer. Follow practical steps and use proven tips to keep your designs safe.

Diode Transil Basics

What Is a Diode Transil?

You want your electronics to last. A diode transil helps you reach that goal. This component acts as a shield for your circuit. When a sudden voltage spike hits, the diode transil reacts instantly. It absorbs the extra energy and keeps your sensitive parts safe. You can think of it as a security guard for your devices. It stands ready to block dangerous surges before they cause damage.

Tip: Always choose a diode transil with a voltage rating just above your normal operating voltage. This ensures fast and reliable protection.

Types: Unidirectional and Bidirectional

You can pick from two main types of diode transil: unidirectional and bidirectional. Each type fits a different need:

Unidirectional diodes work best in single-pole circuits. They protect against voltage spikes that come from one direction. Use these for DC power lines or circuits where current flows one way.

Bidirectional diodes suit bipolar circuits. They guard against voltage spikes from both directions. These are perfect for AC lines or signal paths where voltage can swing positive or negative.

You get the right protection by matching the diode type to your circuit. If you use the wrong type, you risk leaving your electronics exposed.

Common Uses in Electronics

You see diode transil devices in many places. They protect microcontroller inputs, power supply rails, and communication lines. You find them in automotive electronics, industrial machines, and consumer gadgets. Engineers rely on them to prevent costly failures and downtime.

Microcontrollers stay safe from static discharge.

Power supplies avoid damage from lightning or switching surges.

Communication ports resist noise and spikes.

When you add a diode transil to your design, you boost reliability and cut repair costs. Make this small investment, and you protect your project’s future.

How Diode Transil Works

Avalanche Effect and Clamping

You want instant protection when voltage spikes threaten your circuit. The diode transil delivers this by using the avalanche effect. When a high reverse voltage appears, the electric field inside the diode accelerates charge carriers. These carriers smash into atoms, creating more electron-hole pairs. This chain reaction boosts the current flow rapidly. The avalanche effect lets the diode clamp the voltage, stopping it from rising above a safe level. Your sensitive components stay protected, even during sudden surges.

Note: The avalanche effect means the diode responds in real time, so you never have to worry about delays in protection.

Handling Voltage Spikes

Voltage spikes can destroy your electronics in seconds. You need a solution that reacts faster than the threat. The diode transil steps in immediately. When a spike hits, the diode clamps the voltage and absorbs the excess energy. You keep your microcontrollers, sensors, and power rails safe. You avoid costly repairs and downtime. The diode transil works best when you select the right clamping voltage for your circuit. Place it close to the part you want to protect, and you get maximum benefit.

Comparison with Other Protection Devices

You have options for circuit protection, but not all devices perform the same. The diode transil stands out for its speed. It reacts in less than a nanosecond, much faster than metal oxide varistors (MOVs), which respond in the nanosecond range. MOVs absorb more energy, but they act slower. If you need lightning-fast response, the diode transil is your best choice. You get reliable protection for delicate electronics, especially where speed matters most.

Tip: For high-speed digital circuits, always choose the fastest protection device available. The diode transil gives you the edge.

Selecting the Right Diode Transil

Key Specs: Clamping Voltage & Surge Current

You want your circuit to survive real-world surges. To do that, you must focus on two specs: clamping voltage and maximum surge current. Clamping voltage tells you the highest voltage the diode transil will allow during a spike. Always pick a clamping voltage just above your normal operating voltage. For example, in a 12V automotive circuit, you should look for a low clamping voltage that stays safe for your components. Maximum surge current shows how much energy the diode can absorb in a short burst. In automotive applications, a 30A surge current rating (for an 8/20 microsecond pulse) gives you strong protection. If you ignore these specs, you risk leaving your electronics exposed to damage.

Matching Ratings to Your Circuit

You need to match the diode’s ratings to your circuit’s needs. Start by choosing the right type: unidirectional diodes work best for DC circuits, while bidirectional diodes protect AC or data lines. Place the diode close to connectors or sensitive parts to stop surges before they reach critical components. Use wide traces and ground pours on your PCB. This helps the diode handle high currents without overheating or failing. When you follow these steps, you give your circuit the best chance to survive voltage spikes.

Pick unidirectional for DC, bidirectional for AC or data.

Place diodes near connectors.

Use wide traces and solid ground connections.

Using Datasheets for Selection

You should always check the datasheet before you buy or install a diode transil. Look for these key parameters:

Standoff voltage: This is the highest voltage the diode can handle without conducting. Make sure it sits above your circuit’s normal voltage.

Breakdown voltage: The voltage where the diode starts to conduct during a surge. It must fit your rail voltage so the diode does not trigger during normal operation.

Clamping voltage: The peak voltage during a surge. It must stay below the maximum rating of your protected parts.

Peak pulse power or current: This tells you how much energy the diode can absorb. Match this to the worst-case surge your circuit might see.

Capacitance: Important for high-speed data lines. Lower capacitance means less signal distortion.

Polarity: Choose unidirectional for DC, bidirectional for AC.

By checking these specs, you make sure your protection is both strong and reliable. Never skip the datasheet—your circuit’s safety depends on it.

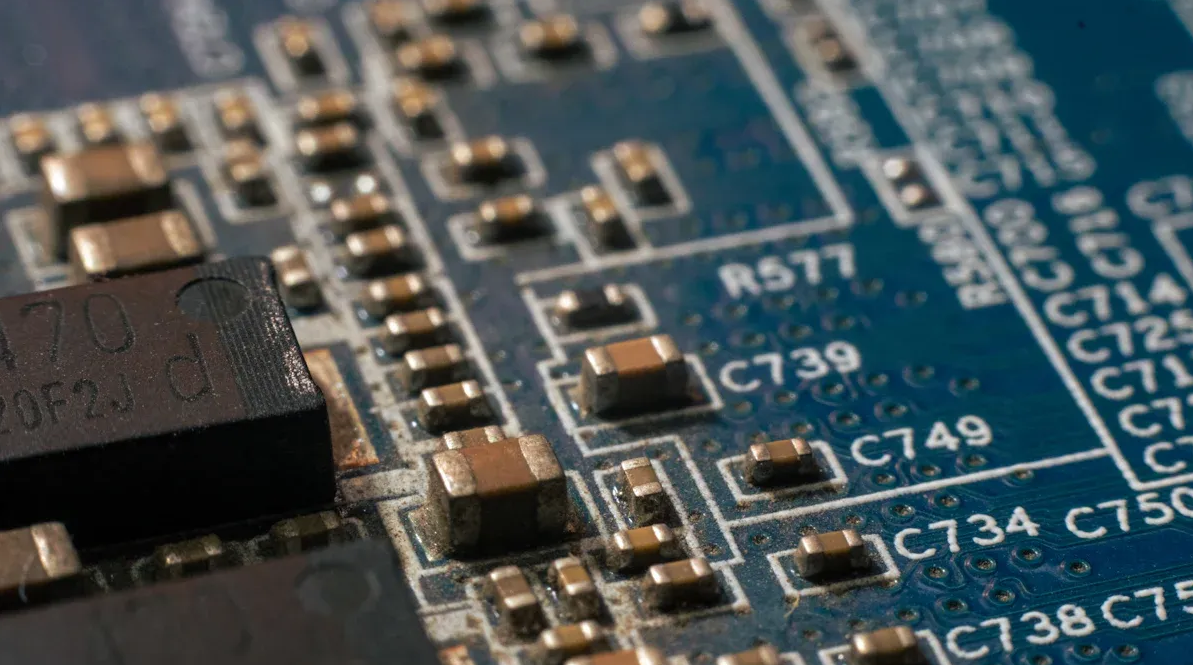

Implementing Diode Transil in Circuits

Image Source: unsplash

Parallel Connection and Orientation

You want your surge protection to work every time. To achieve this, always connect your diode transil in parallel with the load you want to protect. This setup lets the diode react instantly to voltage spikes, shunting excess energy away from your sensitive components. If you need to use multiple diodes for higher protection, choose diodes with the same part number and from the same production batch. This ensures they share the current evenly and prevents one diode from carrying too much of the surge.

To maximize surge protection when connecting TVS diodes in parallel, use identical diodes and test them with a modest waveform. This helps you group diodes with similar voltage characteristics, so no single diode gets overloaded.

Orientation matters. For DC circuits, use a unidirectional diode with the correct polarity. The cathode should face the positive voltage. If you install it backward, you risk blocking the supply voltage or causing a short circuit. In AC or bidirectional signal lines, use a bidirectional diode. This type protects against both positive and negative voltage swings, making it ideal for signals that fluctuate above and below ground.

Placement and PCB Layout Tips

You want the fastest response to voltage spikes. Place the diode transil as close as possible to the point where surges can enter your circuit, such as connectors or exposed pads. This placement reduces the distance the surge travels before being clamped, which improves protection. Keep the traces between the diode and the protected component short and wide. Avoid using vias in these traces, as they add unwanted inductance and slow down the response.

Place the diode near the input connector or ESD source.

Keep the ground return path from the diode short.

Avoid stubs and vias in the trace connections.

When you minimize trace length and keep the diode close to the entry point, you reduce parasitic inductance and electromagnetic interference. This setup lets your diode clamp voltage spikes more effectively and keeps your circuit safe.

Grounding and Current Limiting Resistors

A solid ground connection is essential for effective surge protection. Connect the ground side of your diode transil directly to a low-impedance ground plane. This path allows surge currents to flow away quickly, preventing damage to your components. If your ground path is too long or narrow, the diode cannot respond as fast, and your protection weakens.

You might consider adding a current limiting resistor, but use caution. Placing resistance before the diode can delay clamping and allow higher voltages to reach your circuit. Instead, focus on keeping the path to ground as short and direct as possible. Only use resistors if your application specifically requires them for signal integrity or other reasons.

Common Mistakes to Avoid

You want your protection to work, not fail. Avoid these common mistakes:

Adding series resistance before the diode. This can cause higher voltages before clamping starts. Always use a low-impedance path.

Poor PCB layout. If you place the diode far from the entry point or use long, narrow traces, you reduce its effectiveness.

Relying only on internal protection in ICs. Most chips need extra external protection for real-world surges.

Installing a unidirectional diode with the wrong polarity. This can block your supply voltage or even short-circuit your power rail, leading to overheating or failure.

Take these steps and you will build robust, reliable surge protection. Your circuits will last longer, and you will avoid costly repairs. Choose the right diode transil, install it correctly, and follow best practices for layout and grounding. Your electronics deserve the best defense.

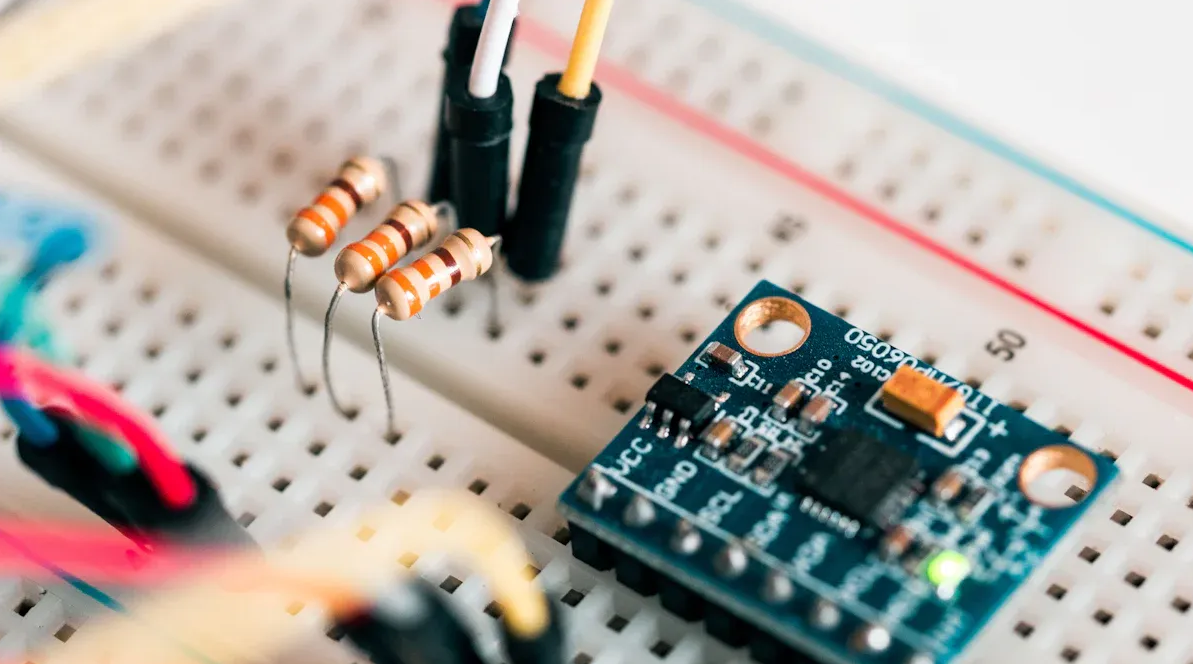

Real-World Applications

Image Source: pexels

Microcontroller Input Protection

You want your microcontroller to survive static shocks and voltage spikes. A diode transil gives you that protection. Place it right at the input pin, and it clamps dangerous voltages before they reach your chip. Many engineers choose compact, low-capacitance models for this job. For example, you can use devices like ESDA-1K or PESD24VS1UB,115 for portable electronics and data lines. These diodes react quickly and keep your signals clean. Lower capacitance means your high-speed data stays sharp, while higher voltage ratings handle bigger surges.Tip: Always select a diode with a voltage rating just above your normal signal level. This ensures fast response and reliable protection.

Power Supply Safeguarding

You want your power rails to stay safe from lightning, switching surges, or wiring faults. TVS diodes work perfectly for protecting 3.3V, 5V, and 12V rails in industrial automation. Choose your diode by checking the reverse standoff voltage, breakdown voltage, clamping voltage, peak pulse current, and capacitance. Place the diode close to the power connector. This setup blocks surges before they can travel down the line and damage your sensitive equipment.

Pick a diode with a standoff voltage above your supply voltage.

Make sure the clamping voltage is below your component’s maximum rating.

Use a low-capacitance part for fast digital rails.

You get peace of mind and fewer failures when you protect your power rails this way.

Automotive and Industrial Uses

You face tough conditions in automotive and industrial environments. Automotive TVS diodes must meet strict standards like AEC-Q101. They work from -55°C to +150°C and handle frequent, powerful transients. You need this level of durability for critical car systems. In industrial settings, you can use diodes with a wider range of packages and lower cost. These diodes still protect against surges, but you match them to your specific application. Automotive diodes cost more because they last longer and survive harsher conditions. Industrial diodes offer flexibility and value for less demanding jobs.

Note: Always check the certification and temperature range before you choose a diode for automotive or industrial use. This step ensures your protection matches your environment.

Place your TVS diodes close to exposed conductors and keep traces short. This boosts response time and keeps your devices safe. Apply these best practices in your next project. For advanced knowledge, explore detailed brochures and catalogs that highlight the latest advancements and help you choose the right components.