What Is an Accelerometer Sensor?

Accelerometer sensors are the invisible technology that detects movement in many devices we use daily. Actually, these inertial sensors measure the change in velocity (acceleration) of an object over time, allowing our smartphones to rotate screens, fitness trackers to count steps, and cars to deploy airbags during sudden impacts.

When we look at how an accelerometer works, we find fascinating technology at play. Most accelerometer sensors operate based on the piezoelectric effect, while others utilize internal capacitive plates that change their relationship as the device moves. Essentially, these sensors can detect tilt, vibration, and impact, making them crucial components in modern electronics. Whether it's the three-axis sensors powering drones and virtual reality devices or the ICP® accelerometers measuring vibration and shock with output voltages of ±5 volts, these remarkable tools have transformed our interaction with technology.

Understanding the Basics of Accelerometers

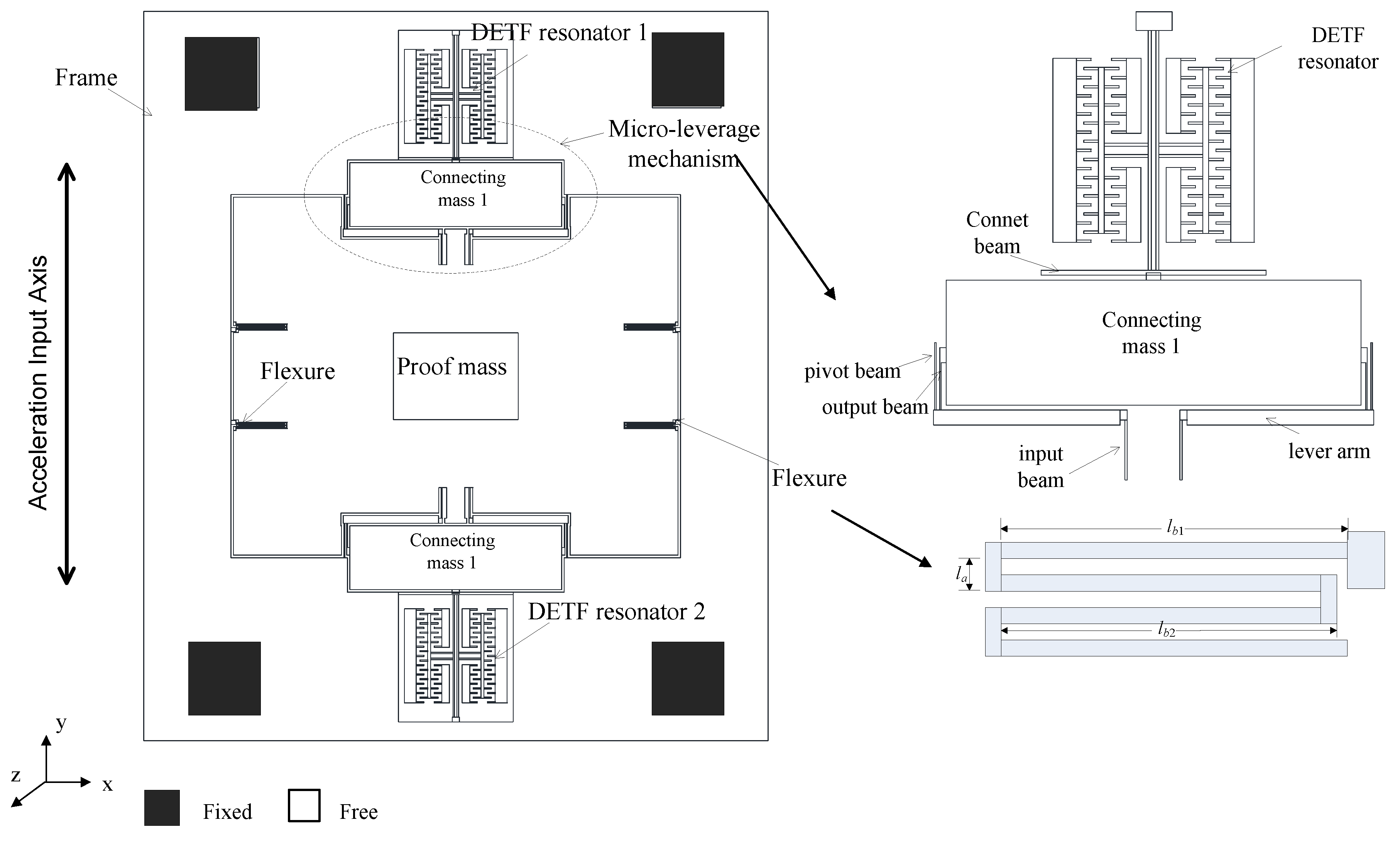

Image Source: MDPI

Understanding the Basics of Accelerometers

What is an accelerometer sensor?

The accelerometer sensor stands as a sophisticated transducer that measures proper acceleration—the acceleration experienced by an object relative to an observer in free fall. Unlike coordinate acceleration, proper acceleration captures the forces that you actually feel. For instance, an accelerometer at rest on Earth's surface will measure approximately 9.8 m/s² (1g) upwards due to the normal force opposing gravity.

Most accelerometer sensors function through a surprisingly simple principle: they contain a tiny mass attached to a spring enclosed within a housing. As the device experiences acceleration, this mass moves, compressing or stretching the spring. The resulting displacement is then measured and converted into electrical signals.

Modern accelerometers typically employ one of three technologies: piezoelectric (generating electrical charge under stress), capacitive (measuring changes between microstructures), or MEMS (Micro-Electro-Mechanical Systems). MEMS technology has particularly transformed this field by enabling high-precision measurements in extraordinarily compact forms.

How does it differ from gyroscopes?

The fundamental difference between accelerometers and gyroscopes lies in what they measure. Accelerometers detect linear acceleration along axes, focusing on changes in velocity and position. In contrast, gyroscopes measure rotational speed or angular velocity—the rate at which an object rotates.

Furthermore, accelerometers can detect tilt, vibration, and impact, making them ideal for orientation sensing. However, they cannot distinguish between acceleration from movement and gravity's pull. This limitation becomes particularly evident in applications like aircraft navigation, where an accelerometer alone cannot reliably determine orientation during movement.

Why accelerometers matter in modern tech

Accelerometer sensors have become indispensable across numerous industries. In consumer electronics, they enable screen rotation in smartphones and step counting in fitness trackers. Additionally, they play critical roles in automotive safety systems by triggering airbag deployment during collisions.

Beyond consumer applications, these sensors are vital in industrial machinery for vibration monitoring and condition analysis. In aerospace, they assist with navigation and flight attitude adjustments. Moreover, medical devices utilize accelerometers for tracking patient movement and detecting falls in elderly care.

The versatility of accelerometer sensors stems from their ability to measure both static forces (like gravity) and dynamic forces (such as vibration or shock). This dual capability, coupled with advancements in miniaturization and power efficiency, has made them fundamental components driving technological innovation across multiple sectors.

How to Use an Accelerometer Sensor

Getting an accelerometer up and running in your project requires understanding three key aspects: proper connections, appropriate power, and data interpretation. Let's break down each component for seamless integration.

Connecting to microcontrollers (I2C, SPI, analog)

Accelerometer sensors communicate through three primary interfaces, each with distinct advantages. First of all, analog accelerometers output varying voltage levels that correspond to acceleration measurements, requiring an analog-to-digital converter (ADC) on your microcontroller to read these values. These tend to be less expensive but more susceptible to electrical noise.

Digital accelerometers communicate through either I2C or SPI protocols, offering greater functionality and noise resistance. For instance, the popular ADXL345 supports both interfaces—connecting CS pin to VDD enables I2C mode, while toggling CS signals the beginning and end of SPI transmissions.

Pulse-width modulation (PWM) accelerometers output square waves with varying duty cycles that change with acceleration. This method falls between analog and digital in terms of complexity.

When connecting to an Arduino or similar board, the wiring is straightforward. For analog accelerometers, connect the X, Y, and Z output pins to analog input pins on your microcontroller. For digital interfaces, connect SCL (Serial Clock) and SDA (Serial Data) pins to your microcontroller's corresponding I2C pins.

Power requirements and logic levels

Accelerometer sensors typically operate on low voltage and draw minimal current. Most devices require supply voltages between 3.3V and 5V, while drawing current in the micro (µ) or milli-amp range. For example, the BMA530 accelerometer consumes only 125 µA in high-performance mode and 18 µA in low-power mode.

Logic levels require careful consideration, especially when mixing 3.3V and 5V systems. Although many breakout boards include onboard voltage regulators and level shifters, mismatched logic levels can damage your sensor. Generally, a 3.3V device sending signals to a 5V system works fine, but the reverse requires level shifting to avoid damage.

Reading and interpreting output data

Once connected, understanding the data requires knowing your sensor's specific characteristics. Digital accelerometers typically output 16-bit values in two's complement form, while analog sensors output voltages proportional to acceleration.

For analog sensors, a reading of approximately half the supply voltage (e.g., 1.65V for a 3.3V supply) typically indicates 0g (no acceleration). Values above or below this baseline represent positive or negative acceleration respectively.

To convert raw data to meaningful measurements, divide by your sensor's sensitivity factor. For example, dividing accelerometer readings by 16,384 converts raw data to g-forces for some sensors. Meanwhile, the ADXL337 measures ±3g range while the ADXL377 measures ±200g, requiring different scaling factors despite identical connection methods.

Remember that orientation affects readings—at rest, an upright accelerometer will register approximately 1g on its Z-axis due to Earth's gravity.

Choosing the Right Accelerometer for Your Needs

Selecting an appropriate accelerometer requires careful consideration of several factors to ensure accurate measurements for your specific application.

Measurement range and sensitivity

The measurement range defines the maximum acceleration your sensor can accurately record. Consequently, if your accelerometer has a sensitivity of 100 mV/g, it produces a 1V output when measuring 10g acceleration. For high-amplitude vibrations, low-sensitivity accelerometers work best, whereas high-sensitivity units excel with low-amplitude applications. Remember that wider measurement ranges typically result in larger residual noise levels.

Number of axes (1D, 2D, 3D)

Single-axis accelerometers measure acceleration along one direction only, making them suitable for mechanical vibration monitoring. Conversely, triaxial accelerometers create 3D acceleration vectors through orthogonal components, ideal when determining lateral, transverse, or rotational vibration types. Importantly, using three separate 1D accelerometers cannot match the precision alignment of a manufactured 3D unit.

Bandwidth and frequency response

Bandwidth represents the highest frequency signal an accelerometer can sample without aliasing. Notably, it's specified as the frequency range where response magnitude remains within acceptable deviation from DC value. A wider bandwidth allows for diagnosing a broader range of machine faults.

Environmental and mounting considerations

The mounting method significantly impacts frequency response. Stud mounting provides the best coupling and highest frequency response. Alternatively, adhesives offer good performance with proper preparation. Temperature affects piezoelectric materials, causing sensitivity variations. For extreme environments, stainless steel packaging protects against corrosion and chemicals.

Future Trends and Innovations in Accelerometer Technology

The horizon for accelerometer technology expands as researchers push boundaries in four key areas.

AI integration and edge computing

Edge computing brings data processing directly to accelerometer sensors, reducing cloud dependency and enabling real-time analysis. This approach decreases latency issues in critical applications. Recent accelerometers now incorporate machine learning cores that classify transportation methods, detect dropping events, and identify excessive vibrations. Indeed, these intelligent sensors can perform inference directly within the device, dramatically extending battery life while providing immediate feedback.

Ultra-low power and energy harvesting

Battery constraints are being overcome through remarkable efficiency improvements. Modern accelerometers like the BMA400 draw only 14 μA at highest performance—ten times less than previous generations. Furthermore, harvesting kinetic energy from human movement creates opportunities for truly battery-free wearable devices. These self-powered systems can both collect motion data and generate electricity simultaneously.

Miniaturization and flexible sensors

Beyond size reduction, researchers are developing flexible accelerometers that conform to complex surfaces. Skin-inspired sensors utilize serpentine interconnects and island-bridge configurations to maintain functionality during bending and stretching. Additionally, miniaturization efforts now aim to create sensors merely 10×10 μm² through quantum tunneling techniques.

Healthcare and smart city applications

The medical accelerometer sensor market is projected to reach $7.30 billion by 2028, growing at 13.3% CAGR. These sensors enable fall detection in elderly care, gait analysis for neurological assessment, and continuous patient monitoring. Within urban environments, accelerometers assist with structural health monitoring and traffic management without requiring power-hungry GPS technology.

Conclusion

Accelerometer sensors have undoubtedly become essential components in countless devices we use daily. Throughout this guide, we've explored how these remarkable sensors detect movement by measuring changes in velocity, whether through piezoelectric effects or capacitive plates. Additionally, we've seen how they differ from gyroscopes by measuring linear acceleration rather than rotational movement.

The practical applications of accelerometers extend far beyond smartphone screen rotation. These sensors play crucial roles in automotive safety systems, industrial machinery monitoring, medical devices, and aerospace navigation. Their ability to detect both static and dynamic forces makes them versatile tools across multiple industries.

When implementing accelerometers in your projects, remember to consider the appropriate interface (analog, I2C, SPI, or PWM), power requirements, and data interpretation methods. Choosing the right accelerometer depends on several factors, including measurement range, sensitivity, number of axes, and environmental conditions.

Looking ahead, accelerometer technology continues to evolve rapidly. AI integration enables on-device data processing, while energy harvesting techniques promise battery-free operation. Miniaturization advances create increasingly smaller sensors, and flexible designs open up new possibilities for wearable applications.

Accelerometers might seem complex at first glance, but understanding their fundamentals allows anyone to harness their capabilities. Whether you're a hobbyist working on a simple motion-detecting project or a professional designing sophisticated systems, these sensors offer remarkable functionality in surprisingly small packages. The accelerometer's journey from specialized equipment to ubiquitous component highlights how fundamental technologies can transform our daily interactions with the world.

FAQs

What is the primary function of an accelerometer sensor?

An accelerometer sensor measures changes in velocity or acceleration of an object over time. It detects movement, tilt, vibration, and impact, enabling various applications in smartphones, fitness trackers, automotive safety systems, and industrial machinery.

How does an accelerometer sensor work?

Most accelerometer sensors contain a tiny mass attached to a spring within a housing. When the device experiences acceleration, the mass moves, compressing or stretching the spring. This displacement is then measured and converted into electrical signals, which can be interpreted as acceleration data.

What's the difference between an accelerometer and a gyroscope?

While both are inertial sensors, accelerometers measure linear acceleration along axes, detecting changes in velocity and position. Gyroscopes, on the other hand, measure rotational speed or angular velocity - the rate at which an object rotates.

How do I choose the right accelerometer for my project?

Selecting the right accelerometer depends on several factors, including the required measurement range, sensitivity, number of axes (1D, 2D, or 3D), bandwidth, and environmental conditions. Consider your specific application needs and the accelerometer's specifications to make the best choice.

What are some future trends in accelerometer technology?

Future trends in accelerometer technology include AI integration for on-device data processing, ultra-low power consumption and energy harvesting capabilities, further miniaturization and development of flexible sensors, and expanded applications in healthcare and smart city infrastructure.