Understanding Battery Connectors: A Guide to Three Essential Types

A battery is a source of stored power. But that power is useless unless it can be delivered to a device. The component that makes this delivery possible is the battery connector. This device is a critical link. It creates a physical and electrical bridge between the battery terminals and the circuit that needs power. Without a reliable connection, even the most powerful battery cannot perform its job.

The world of battery terminals and their corresponding device-side interfaces is vast. The design of these components varies greatly. The design depends on the battery's size, its chemistry, the amount of current it must provide, and the physical demands of the application. A tiny connector for a hearing aid battery is very different from a large, heavy-duty terminal used in an electric vehicle.

Understanding the fundamental categories of these power-transfer components is important for anyone working with electronic design or repair. We can group the thousands of available models into logical types based on their form and function.

The First Type: Spring Contact Connectors

The first essential type of battery connection solution is the spring contact. This is perhaps the most common type of battery interface found in small to medium-sized consumer electronic devices. You have likely seen them many times. Think of the battery compartment in a television remote control, a flashlight, or a children's toy. The small metal tabs and coils that press against the ends of the batteries are spring contact connectors.

The basic principle of a spring contact is very simple. It uses the mechanical force of a compressed or bent piece of metal to maintain a solid electrical connection with a battery terminal. The "spring" action ensures that the contact is always pushing against the battery. This constant pressure is important. It helps to overcome small surface imperfections. And it maintains the connection even when the device is subject to minor shocks or vibrations.

These components are typically made from metals that have good spring properties and good electrical conductivity. Common materials include beryllium copper and phosphor bronze. These materials can be bent or compressed many times without losing their shape. And they are often plated with other metals like nickel, tin, or gold. The plating helps to prevent corrosion and improves the electrical performance of the connection. Corrosion is a major enemy of a good battery connection because it can create a layer that resists the flow of electricity.

There are many different shapes and styles of spring contacts. One common form is the coil spring. This is the type that looks like a small cone-shaped spring. It is often used for the negative terminal of a cylindrical battery, like an AA or AAA cell. Another common form is the leaf spring. This is a flat or shaped piece of metal that acts like a flexible tab. These are often used for the positive terminal or for connecting to the flat surfaces of coin cell batteries.

The main advantage of spring contacts is their simplicity and low cost. They are easy to manufacture. And they allow for very easy battery installation and replacement by the user. The design of the battery compartment guides the battery into the correct position. The spring contacts then automatically establish the connection.

But there are also limitations. Spring contacts are generally not suitable for high-current applications. The small point of contact can overheat if too much current flows through it. They are also not ideal for environments with very strong vibrations. A hard jolt can cause the spring to momentarily lose contact with the battery. This creates a brief power interruption that can reset a device's electronics. For these reasons, you will mostly find spring contacts in low-power, non-critical devices.

Let's consider some specific applications. In a digital camera, spring contacts connect to the AA or lithium-ion battery pack. The contacts are designed to be durable enough for repeated battery changes. In a wireless computer mouse, spring contacts provide a simple and compact way to power the device. The low power draw of the mouse makes this type of connection ideal. In medical devices like glucose meters, the reliability of the spring contact is very important. So these contacts are often plated with gold to ensure the best possible long-term connection.

In summary, spring contacts are a fundamental type of connector for battery power. They are perfect for many everyday electronic devices. They provide a cost-effective and user-friendly solution for applications that do not involve high currents or extreme physical stress.

The Second Type: Board-Mounted Mating Connectors

The second essential type is the board-mounted mating connector. This category represents a more robust and formal connection method compared to simple spring contacts. These systems consist of two distinct parts that are designed to plug into each other. One part is mounted directly on the Printed Circuit Board (PCB) of the device. The other part is attached to the battery pack, usually via wires.

This two-part system creates a very secure and reliable connection. It is the preferred method for devices that require higher currents, greater reliability, or a more defined connection point than spring contacts can offer. This approach is very common in devices with rechargeable, custom-shaped battery packs.

Let's look at the structure more closely. The connector on the PCB is typically a header or a socket. It is soldered onto the board using either through-hole or surface-mount techniques. The corresponding connector on the battery pack is a plug. This plug is attached to wires that lead to the battery cells. The plug and socket have housings, which are usually made of molded plastic. These housings serve several functions. They hold the metal terminals in their correct positions. They protect the terminals from damage and short-circuiting. And they provide keying features. Keying means the plug is shaped in a unique way so it can only be inserted in the correct orientation. This prevents the user from connecting the battery backwards, which could damage the device or the battery.

The terminals inside these componentsare precisely engineered pins and sockets. They provide a much larger contact surface area than a simple spring contact. This larger surface area is better for handling higher electrical currents. More current can flow without the risk of overheating. The connection is also much more resistant to vibration and shock. Once the plug is inserted into the socket, it is held firmly in place, often with a latching mechanism that clicks to confirm a secure connection.

The use of board-mounted mating systems is widespread in modern electronics. Laptops are a perfect example. The removable battery in a laptop has a connector that plugs into a matching part on the laptop's motherboard. This connection has to carry enough current to power the entire computer. It also includes extra pins for communication, allowing the laptop to monitor the battery's charge level and temperature.

Professional power tools are another key application. A cordless drill, for example, uses a slide-on battery pack. The pack has a heavy-duty connector that mates with a corresponding part on the tool. This connection must handle very high currents to power the drill's motor. It must also be extremely durable and able to withstand the harsh conditions of a construction site.

Drones and radio-controlled vehicles are also heavy users of these components. The lithium-polymer (LiPo) battery packs used in these hobbies have specific multi-pin connectors. These not only provide power to the motors but also allow for "balance charging." Balance charging means each cell within the battery pack is charged and monitored individually. This requires a connector with multiple pins to access each cell.

The main advantage of board-mounted mating connectors is their reliability and performance. They provide a secure, keyed, and high-current capable link between the battery and the device. This makes them ideal for applications where a power failure would be a major problem.

The disadvantage is higher cost and complexity compared to spring contacts. A two-part system is more expensive to manufacture and assemble. The battery pack itself also becomes more complex because it needs to have wires and a plug attached. But for many products, this trade-off is necessary to achieve the required level of performance and safety.

In short, board-mounted mating systems are a step up in robustness. They are the go-to solution for connecting custom battery packs in a huge range of devices, from portable medical equipment to high-performance electronics.

The Third Type: Cable and Lug Terminals

The third essential type of battery connection involves cables and lug terminals. This category covers the methods used for very large batteries that deliver very high amounts of power. These are the kinds of connections you find in automotive, marine, solar power, and other heavy-duty industrial applications. In these systems, the electrical currents are so high that the smaller connectors used in consumer electronics would instantly fail.

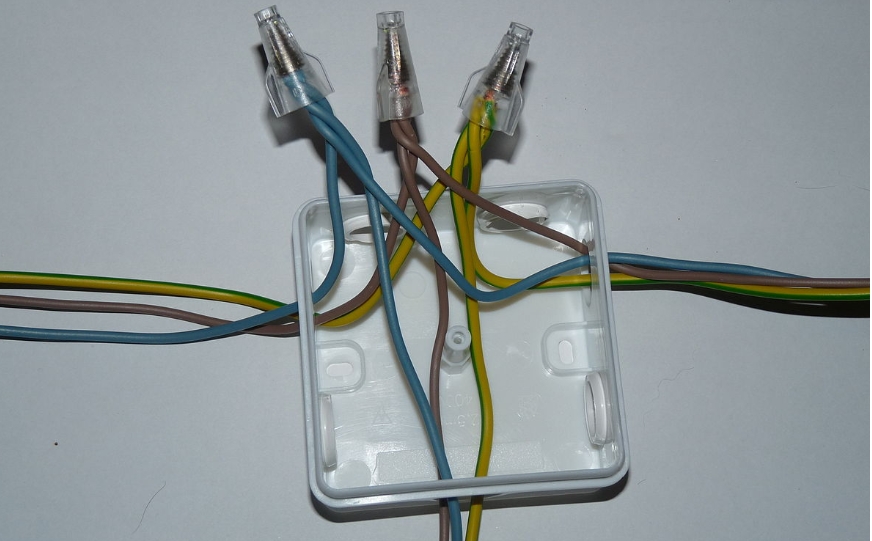

A lug terminal is a heavy-gauge metal connector that is attached to the end of a large electrical cable. The lug has a flat, ring-shaped or fork-shaped end with a hole in it. This flat end is designed to be securely fastened to a threaded post or bolt on the battery terminal. The other end of the lug has a barrel. The bare end of the large cable is inserted into this barrel and then permanently attached. This attachment is usually done by a process called crimping, where a special tool is used to compress the barrel tightly around the cable, creating a solid mechanical and electrical bond. Sometimes, solder is also used to reinforce the connection.

The batteries used in these applications are often lead-acid, AGM, or large lithium-ion types. They have threaded posts, studs, or flat pads with bolt holes as their terminals. The lug on the end of the cable is placed over the post or lined up with the hole. Then a nut or a bolt is used to clamp it down tightly.

This method creates an extremely strong and secure connection. The large surface area of the lug pressing against the battery terminal allows for the transfer of very high currents, often hundreds or even thousands of amps. The bolted connection is also extremely resistant to vibration and shock, which is why it is the standard in all vehicles.

The cables used are also very thick to handle the high current without overheating. The thickness, or gauge, of the cable is chosen based on the maximum current it needs to carry and its length. Using a cable that is too thin for the current load is a serious fire hazard.

Let's look at the most common example: a car battery. The car's electrical system connects to the battery's lead posts using clamp-style lug terminals. These clamps are tightened with a bolt to ensure a firm grip on the posts. One large cable goes to the starter motor, which draws a huge amount of current to start the engine. Another cable goes to the fuse box to power the rest of the car's electronics.

Off-grid solar power systems are another major application. Large banks of deep-cycle batteries are used to store energy collected by solar panels. These batteries are connected to each other and to power inverters using thick cables with ring lug terminals. These connections must be very secure and have low resistance to avoid wasting precious stored energy.

Electric vehicles (EVs) also rely on this type of connection. The main high-voltage battery pack in an EV is made up of many smaller battery modules. These modules are linked together with busbars, which are solid metal strips that function like heavy-duty cables. The final connections from the pack to the vehicle's main power electronics are made with very large cables and bolted lugs.

The key advantage of cable and lug terminals is their ability to handle immense amounts of power safely and reliably. They create a low-resistance path for the current, which is crucial for efficiency. And their bolted-down nature makes them incredibly robust.

The main disadvantage is their size, weight, and lack of user-friendliness for quick changes. These connections are meant to be semi-permanent. They are installed with tools and are not designed for frequent disconnection and reconnection. They are a pure engineering solution for high-power needs, where convenience is less important than safety and raw performance.

In conclusion, cable and lug terminals represent the heavy-duty end of the battery connection spectrum. They are the essential method for linking high-capacity batteries to power-hungry machines and systems, forming the backbone of the electrical infrastructure in vehicles and industrial power applications.

Conclusion

We have explored three fundamental types of connectors for battery applications. We have seen spring contacts, board-mounted mating connectors, and heavy-duty cable and lug terminals. Each type serves a distinct purpose and is designed for a specific scale of power delivery.

Spring contacts offer a simple and low-cost solution for low-power consumer devices where easy battery replacement is important.

Board-mounted mating connectors provide a secure, reliable, and higher-performance connection for devices with custom rechargeable battery packs.

And cable and lug terminals are the robust solution required for high-power systems like those found in vehicles and industrial settings.

The choice of a battery connection method is a critical design decision. An engineer must consider the electrical requirements, such as current and voltage. They must think about the physical environment, including vibration and exposure to moisture. They must also consider the user experience, like how often the battery needs to be changed. Finally, cost and manufacturing complexity are always important factors.

From the smallest electronic gadget to the largest electric vehicle, the humble battery connector plays a vital role. It is the gatekeeper of power. Choosing the right type of gate ensures that the power is delivered safely, reliably, and efficiently, allowing the device to perform its function as intended.