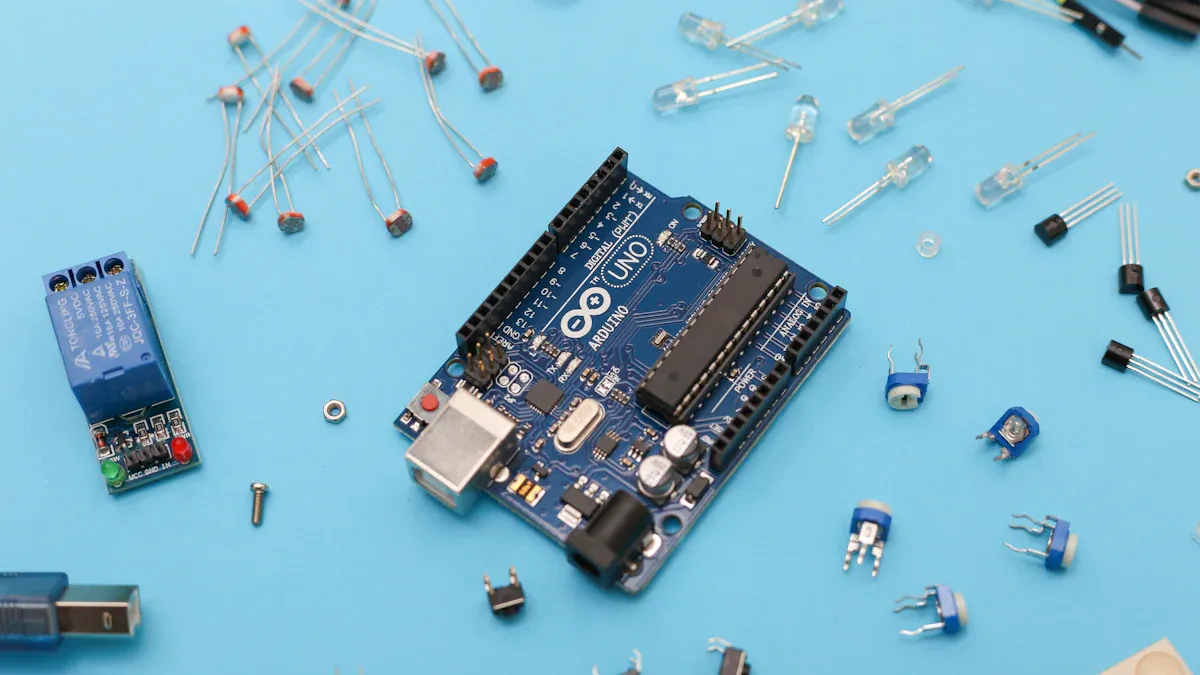

Choosing the Right Electronic Components for Reliable Project Performance

Image Source: unsplash

If you want your project to work every time, you need to pick electronic components that match your needs and work well together. You have to look past just the price tag and check the details—like size, power, and how they handle heat or moisture. Many projects fail when you miss these details. Here are some common problems that can ruin your build:

Bad soldering or using the wrong solder can make connections weak.

Heat and cold can crack electronic components or make them wear out faster.

Dust, moisture, or even insects can get inside and cause shorts or corrosion.

Placing electronic components in the wrong spot, like putting a heat sink near a delicate part, can make things break early.

Picture building a robot for a school fair. If you skip checking these details, your robot might not even turn on when you need it most.

Key Takeaways

Understand what your project needs before picking parts. This helps make sure they fit and work well together. - Look at electrical specs like voltage, current, and temperature. This can help stop damage and failures. - Think about size, mounting, and where the parts will be used. This protects parts from heat, moisture, and shaking. - Choose good quality parts from trusted suppliers. Make sure they have good support and industry certifications. - Plan for future upgrades and keep extra parts. This helps avoid supply problems and makes your project last longer.

Define Requirements

Before you start picking out electronic components, you need to know exactly what your project needs. If you skip this step, you might end up with parts that do not fit, do not work together, or fail when you need them most. Let’s break down the main things you should look at.

Electrical Specs

You want your project to run smoothly, so you must match each component to the right electrical specs. Think about the voltage and current your circuit will use. Make sure every part can handle the power without overheating or breaking down. You also need to check the frequency range, especially if you work with signals or high-speed circuits. Do not forget about temperature—some parts only work well in certain ranges.

Mechanical Needs

You also need to think about the size and shape of each part. If a component is too big, it might not fit on your board. If it is too small, it could be hard to solder or replace. The way you mount each part matters too. Some parts need strong connections, while others can use surface mounting for a smaller footprint. Always check that the footprint matches your PCB layout. If you plan to fix or upgrade your project later, make sure you can reach and replace the parts easily.

Tip: Surface mount parts save space, but through-hole parts are easier to repair.

Environmental Factors

Your project might face heat, cold, moisture, or even vibration. These things can break down electronic components over time. High temperatures can cause parts to expand and crack. Humidity can lead to rust or short circuits. If your project will be outside or in a rough place, pick parts that can handle those conditions. Testing for temperature swings, moisture, and vibration helps you find weak spots before your project fails.

Remember: The right parts keep your project running, even when the environment gets tough.

Electronic Components Selection

Image Source: pexels

Picking electronic components is not just about looks or price. You need parts that work well together and last a long time. It is also important to find parts that are easy to buy. Here are some things to check before you choose.

Quality and Compatibility

You want your project to work every time, so quality is important. Always check if the electronic components meet industry standards. These standards help you know if a part is safe and reliable. They also show if the part is made with good materials. Here is a table with some important standards:

You should also look for certifications like AS 9120, ERAI, or ITAR. These show that the supplier follows strict rules for quality and safety.

When you compare electronic components, always read the datasheet. The datasheet tells you about power, size, pin layout, and how to mount the part. Check the highest ratings for voltage, current, and temperature. Make sure the part can handle what your project needs. Look for things like:

Electrical characteristics (can it handle your circuit?)

Operating temperature range (will it work in your environment?)

Package type and size (does it fit your board?)

Reliability testing and certifications

Tip: If you use parts that follow international standards, your project is safer and less likely to fail.

Cost and Availability

You might want to save money, but cheap parts can cause problems later. If a part fails or is hard to replace, it can cost more. The supply chain for electronic components can change quickly. Sometimes, trade rules or shipping problems make it hard to get parts. Prices can go up or you may have to wait longer.

Here are some things that can affect cost and availability:

Changes in rules or tariffs can slow shipping and raise prices.

Some places, like the US and Asia, need more parts, so supply can be tight.

Companies now order smaller amounts more often, so you need to plan your inventory carefully.

To avoid problems, try these steps:

Pick parts that many suppliers sell.

Do not use rare or special parts unless you must.

Build good relationships with your suppliers.

Have a backup plan if your main part is out of stock.

Note: A part that is easy to buy today might be hard to find next year. Always check if your supplier can keep sending you the same part for as long as you need it.

Lifecycle and Flexibility

Every electronic component has a life cycle. Some, like capacitors, can wear out if you store them too long or use them in tough places. Resistors last a long time if you keep them dry and cool. Microcontrollers usually work for years once you solder them onto your board. But moisture, heat, and even light can make parts wear out faster.

Here are some ways to help your project last longer and stay flexible:

Store parts in a cool, dry place away from sunlight.

Use sealed packaging for parts that do not like moisture.

Test old parts before you use them.

Choose modular parts that you can swap or upgrade later.

Pick microcontrollers with extra memory or pins for future features.

Use standard connectors like USB-C or HDMI to make upgrades easier.

If you plan for upgrades, you save time and money later. For example, if you use modular parts and standard connectors, you can swap out a broken or old part without changing your whole project.

Remember: Good planning now means fewer problems later. Design your project so you can fix, upgrade, or expand it when you need to.

Validate Choices

Simulation Tools

You want your project to work well the first time. Before building, try using simulation tools. These tools let you test your ideas on a computer. You can see how your circuit acts in different situations. For example, you can check what happens if it gets hot or if the voltage changes. This helps you find problems early. It also saves you time and money.

Tip: Try running Monte Carlo simulations. This shows how small changes in your parts can affect your project’s reliability.

Simulation tools are like digital models. You can test electronic components before you build anything. These tools help you see how your design handles temperature swings or voltage spikes. You can also check what happens if part values change a little. This lets you catch mistakes early. You can make better choices and avoid having to redo your work.

Failure Analysis

Even good designs can have problems. You need to think about what could go wrong with your electronic components. Start by looking at common ways things fail:

You can use root cause analysis and FMEA to find out why things fail. Good design means picking the right parts and testing them well. Add safety features like fuses or surge protectors. Watch your project with sensors or alarms to catch problems early. If something fails, figure out why and fix it for next time.

Remember: Careful planning and testing help your project last longer and work better, even in tough conditions.

Avoid Mistakes

Common Pitfalls

You might think picking electronic components is simple if you read the datasheet. But real projects show that is not enough. Many people make the same mistakes again and again.

You can see that just reading datasheets is risky. Real tests show that parts with the same specs can act differently with heat, water, or noise. If you ignore these things, your project might not work outside the lab. Always test your design in real life and leave some extra safety space.

If you pick parts only because they are cheap or easy to get, you might have supply problems later. A part that is easy to buy now might not be around next year, and you may have to change your project.

Maintenance Planning

You want your project to last, so you need a plan for fixing and upgrading it. If you do not manage your parts well, you can have big problems. Storing parts the wrong way can make them rust or stop working. Even if you store them right, all parts get old and may not be made anymore. When that happens, you might need to change your project or pay more for new parts.

Big companies use smart tools to keep track of their parts. They talk to suppliers, keep extra parts, and use software to find risks early. You can do this too. Try these steps:

Pick parts that will be sold for many years.

Stay in touch with your suppliers and ask about parts that will stop being made.

Use designs that let you swap out old parts easily.

Store your parts in a cool, dry place to keep them from aging fast.

Check your parts often and replace any that are old or broken.

Good planning means fewer surprises. If you plan for upgrades and replacements, your project will keep working and stay strong.

You can build reliable projects when you follow a clear plan for picking parts. Start by knowing what your project needs, then test and compare options. Remember to balance performance, cost, and reliability.

Choose trusted suppliers and keep an eye on new trends.

Use tools to check your design before building.

Stay curious and keep learning—your next project will be even better!

FAQ

What should I do if a component is out of stock?

You can look for a similar part from another brand. Check the datasheet to match specs. Ask your supplier for help. Always keep a backup option in your design.

Can I use old or leftover parts from other projects?

You can, but test them first. Old parts might not work well. Store them in a dry, cool place. If you see rust or damage, do not use them.